Wedoany.com Report on Feb 7th, Developing artificial intelligence is a must-answer question, not an optional one.As a national leader in the machine tool sector, China General Technology Group recently held a media communication conference to announce its machine tool industry strategy for the East China region. This initiative aims to address issues such as uneven industrial layout and production bases being far from core markets. It seeks to deeply integrate into and support the construction of national advanced manufacturing industry clusters, ensuring the security, stability, independence, and controllability of the industrial and supply chains.

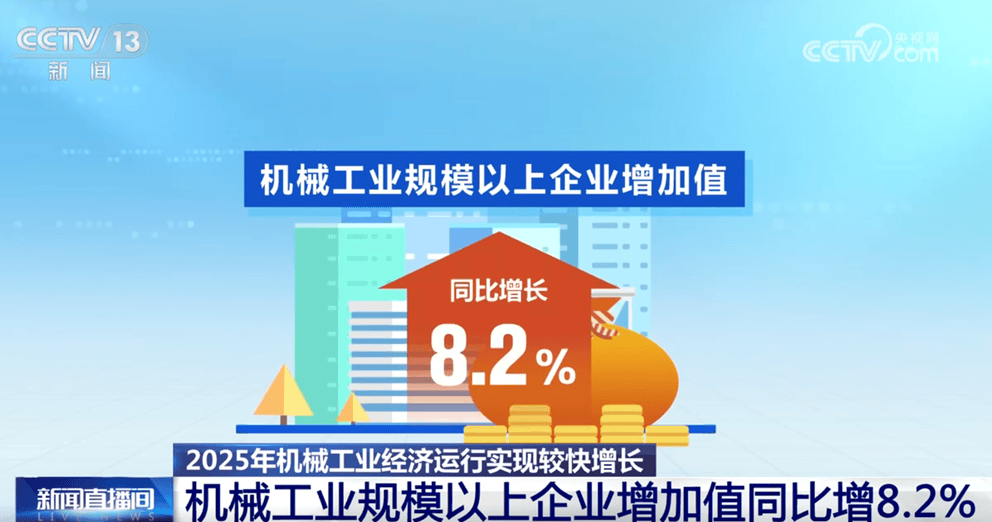

During the recently concluded 14th Five-Year Plan period, national policy support for the machine tool industry continued to intensify. Favorable policies including fiscal and tax subsidies, R&D incentives, and domestic substitution guidance were rolled out intensively. As a result, the machine tool segment of China General Technology Group saw revenue growth exceeding 28% and profit growth surpassing sixfold.

The 15th Five-Year Plan period is a critical time for the development of the machine tool industry. Zhou Zhou, Chief Engineer of China General Technology Group, stated that the group will focus on key areas such as aviation and aerospace to tackle high-end equipment like five-axis linkage and heavy/ultra-heavy machine tools, ensuring the independence and controllability of the industrial chain. Simultaneously, it will provide cost-effective intelligent production lines and customized solutions for industries like automotive and new energy to expand its share in the mid-to-high-end market. The group will coordinate and allocate various resources such as R&D, production, and capital, increase R&D investment, and achieve a two-way concentration of resources towards national strategic priorities and market demand hotspots through integrated management.

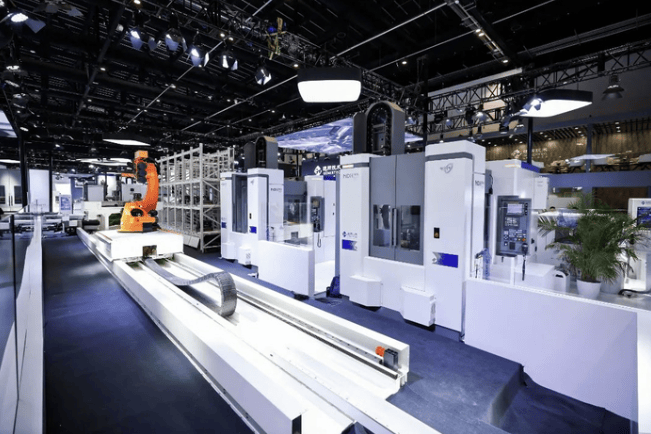

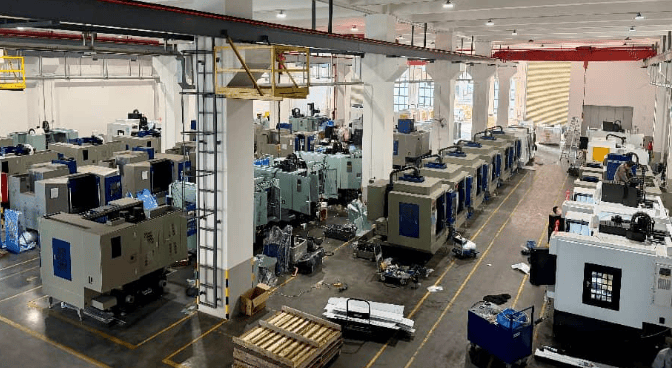

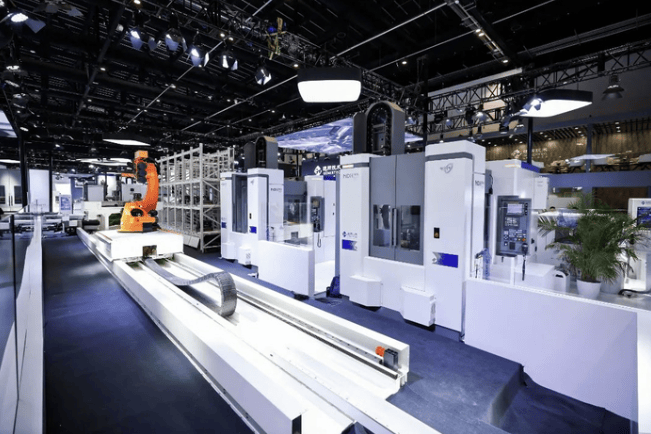

China General Technology Group is advancing a nationwide industrial layout system characterized by "clear division of labor and coordinated linkage." Under this overall framework, different regions assume distinct yet mutually supportive functions. Northeast China focuses on manufacturing capabilities and systematic support, the Beijing-Tianjin-Hebei region concentrates on cutting-edge and common technology R&D, while East China emphasizes the functional positioning of high-end intelligent manufacturing and rapid response to emerging markets.

The current initiatives in East China—including the construction of the Jiangsu Tongzhi CNC Machine Tool Innovation Center, the acquisition of Nanjing No.2 Machine Tool Works, and the establishment of the Composite Material Equipment Company—are precisely aligned with this positioning.

Wang He, Deputy General Manager of China General Technology Machine Tool Co., Ltd., explained that the group's core manufacturing enterprises in the machine tool segment have long been rooted in Northeast China, forming a solid manufacturing foundation and a complete industrial system. This provides stable support for the group's participation in the machine tool industry competition. Building on this foundation, positioning East China as a key strategic region is not an adjustment or weakening of the existing structure. Instead, it is a systematic arrangement made in accordance with industrial development trends, under the premise of coordinating the functional positioning of regions nationwide.

East China is one of the most dynamic regions for emerging industries and high-end application demands. Sectors such as new energy vehicles, medical devices, and the low-altitude economy impose higher and faster requirements for high-performance CNC equipment. This plays a crucial driving role for China General Technology Group in optimizing its product structure, accelerating product iteration, and cultivating key products with market competitiveness. Wang He stated that by establishing a presence in East China, the group can better align with high-end market demands and promote the transformation and upgrade from supplying single equipment to providing comprehensive solutions.

Currently, artificial intelligence is accelerating its deep integration with the real economy, profoundly changing manufacturing production models and economic structures. It has become a key force driving industrial upgrading, bringing new opportunities for the high-end and digital transformation of manufacturing sectors like machine tools.

To promote the intelligent transformation of manufacturing, eight departments including the Ministry of Industry and Information Technology (MIIT) recently jointly issued the "Implementation Opinions on the Special Action for 'Artificial Intelligence + Manufacturing'." The document outlines seven key tasks focusing on innovation foundation, intelligent empowerment and upgrade, and product breakthroughs, aiming to promote the mutual empowerment of AI technology and manufacturing applications and accelerate the intelligent, green, and integrated development of manufacturing.

Zhang Yunming, Vice Minister of the Ministry of Industry and Information Technology, stated at a recent State Council Information Office press conference that for the critical task of achieving new industrialization, developing artificial intelligence is a must-answer question, not an optional one. Efforts will be made on two fronts: one is to strengthen technological supply to promote "intelligent industrialization," and the other is to focus on enabling applications to accelerate "industrial intelligence," thereby driving the high-quality development of the AI industry and empowering new industrialization at a high level.

Su Zili, Chief Accountant of the Machine Tool Research Institute under China General Technology Group, stated that in response to the strategic opportunity of deep AI-manufacturing integration and the group's development needs during the 15th Five-Year Plan period, three core objectives have been set: deep AI empowerment, breakthroughs in intelligent products, and enhancement of the industrial niche. The group will build a comprehensive digital and intelligent empowerment system centered on the entire lifecycle of machine tools—"design-manufacturing-inspection-operation and maintenance."

Specifically, in the design phase of high-end CNC machine tools, the group will build private domain models for machine tool products, integrate historical R&D data, operational condition data, and user feedback to conduct simulation analysis and solution iteration. This aims to promote intelligent optimization of product design, shorten R&D cycles, and reduce trial-and-error costs. In the manufacturing phase, AI-driven production scheduling systems will be introduced to adjust process parameters in real-time based on actual conditions during machining and manufacturing, thereby improving product consistency and the scientific nature of production scheduling.

Furthermore, in the inspection phase, a full-chain inspection system will be established by combining AI technology, visual recognition, laser detection, and other technologies. Simultaneously, a linkage mechanism between inspection data and the design and manufacturing phases will be established to form a closed loop and enhance product quality. In the operation and maintenance phase, innovative intelligent service models will be developed. By integrating digitalization, intelligence, and AI technology, a remote operation and maintenance cloud platform will be built to provide predictive maintenance suggestions, further offering data support for product iteration, upgrade, and personalized customization.