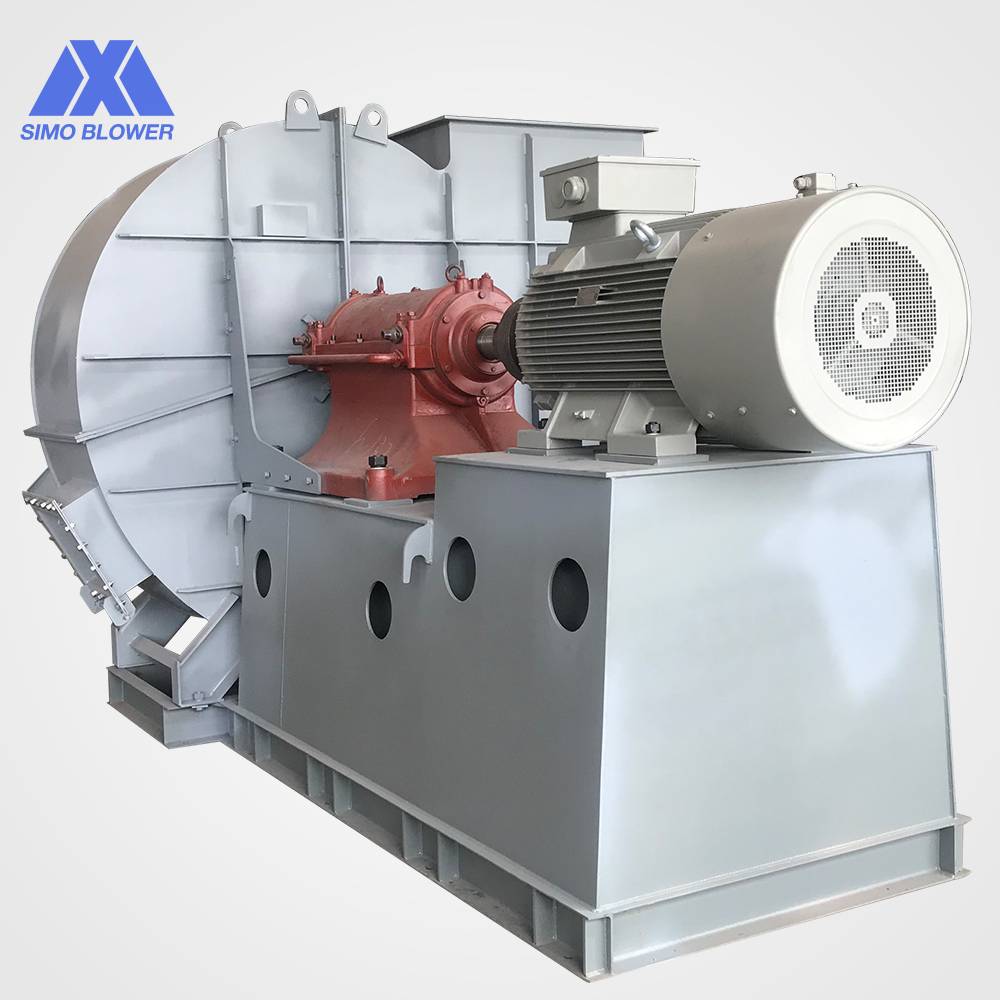

Detailed introduction: This series is suitable for the induced draft system of steam boilers with a capacity of 2-670t/h in thermal power plants, meeting the high-pressure head performance parameters required for fluidized bed boilers. The fans in this series can also be used for dust removal, mine ventilation, and general ventilation systems. The blower transports air, while the induced draft fan transports flue gas or gas with particulate impurities. When the concentration of impurities is less than 200mg/m³, the fan can be used for more than four years. It can also be used when the impurity concentration is higher, but the service life will be shortened. The maximum operating temperature of the induced draft fan should not exceed 250℃. The performance of the fan is represented by parameters such as flow rate, total pressure, shaft speed, shaft power, and efficiency.

Product features:

①Impeller: The impeller is made of 12 backward-curved wing-shaped blades welded between a conical front plate and a flat rear plate. With the wing-shaped blades, the fan ensures high efficiency, low noise, and high strength. The impeller undergoes static and dynamic balancing, ensuring smooth operation. The impellers of both the blower and induced draft fan of the same model are structurally identical.

②Casing: The casing is made of ordinary steel plates welded into a spiral shape. The casing for single-inlet fans comes in three different forms: No. 8-12 casings are made as an integral structure and cannot be disassembled; No. 14-16 casings are made as two-part structures; No. 18-29.5 casings are made as three-part structures. The casing and spiral plates of the induced draft fan are appropriately thickened to prevent wear.

③Inlet: The convergent, streamlined inlet is made as an integral structure and is bolted to the fan inlet side.

④Regulating door: This device is used to adjust the fan flow and is axially installed in front of the inlet. The adjustment range is from 0° (fully open) to 90° (fully closed).

⑤Transmission part: The main shaft of the transmission part is made of high-quality steel, and the fan uses rolling bearings. The bearing box comes in two forms: No. 8-16 uses an integrated cylindrical bearing box, and No. 18-29.5 uses two independent pillow block bearing boxes. The bearing boxes are equipped with thermometers and oil level indicators (only for induced draft fans). The lubricating oil used is 30# mechanical oil, and the oil quantity is implemented according to the oil level indicator. For No. 8-16 integrated cylindrical bearing boxes, when dry oil is used, an oil shield should be added to the side of the bearing box where the ball is located, and the fixing grooves should be interconnected. The induced draft fan is equipped with a water cooling device, so a water pipe must be installed. The water consumption varies with temperature and is generally considered to be 0.5-1m³/h.