Fittings are key components in piping systems used to connect, branch, change direction, or control fluid flow. Their inner walls must be smooth to reduce fluid resistance, and their interfaces are standardized to ensure compatibility. Some fittings integrate sealing surface structures. Fittings enable piping systems to function by fluid guidance, pressure balancing, connection and sealing, and system maintenance. Common types include elbows, tees/crosses, reducers (reducing tees), pipe caps/plugs, unions, and flanges.

The material of fittings needs to be compatible with the characteristics of the medium and operating conditions. For example, carbon steels like Q235, 20# steel are low-cost and suitable for non-corrosive, room-temperature media; stainless steels like 304, 316 have strong corrosion resistance and are used in chemical, food, and pharmaceutical industries; alloy steels like 15CrMo, P91 are heat- and pressure-resistant, suitable for power plant boilers and petrochemical cracking devices; duplex steels like 2205 combine strength and corrosion resistance, used in offshore platforms or chlorinated media environments; PVC, PTFE lined plastic/fittings are used for highly corrosive or high-purity fluids.

The nominal pressure indicates the rated pressure-bearing capacity of fittings and must match the piping system. Low-pressure (PN≤1.6MPa) fittings are used for regular water supply and ventilation systems, typically made from carbon steel or plastic; medium-pressure (PN=2.5~6.4MPa) fittings are commonly used in industrial steam and compressed air systems, with materials upgraded to alloy steel; high-pressure (PN≥10MPa) fittings are used in oil and gas transport and supercritical boilers, requiring forged or thick-walled cast processes; special grades (Class 150~2500) are classified according to ASME B16.5 standards, such as Class 300, which corresponds to PN≈5MPa.

The dimensions of fittings are determined by the piping project requirements. Common parameters include: Nominal Diameter (DN): such as DN15 (½ inch) to DN1200 (48 inches); wall thickness: classified by Schedule (Sch), such as Sch40, Sch80; length/bend radius: long-radius (1.5D) and short-radius (1.0D) elbows, with D being the pipe diameter.

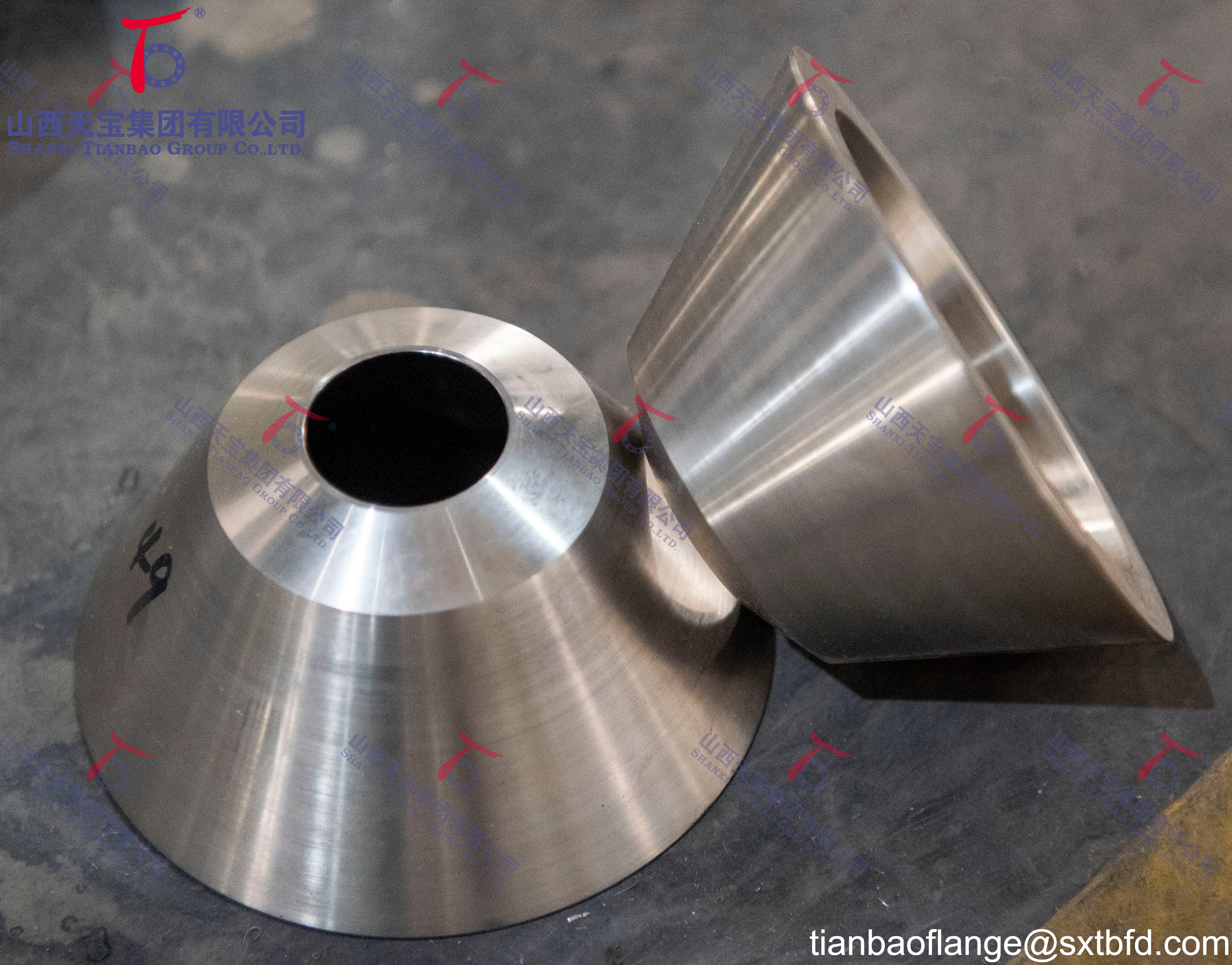

Sealing performance is a core requirement for fittings (especially flanges). Common sealing surface designs include flat face (FF), raised face (RF), ring joint (RTJ), tongue and groove (TG), and threaded seals.

As the "joints" of piping systems, the structure, material, and sealing design of fittings must match fluid characteristics, pressure and temperature, and maintenance needs. From carbon steel elbows to duplex steel flanges, from DN15 micro-joints to DN1200 giant tees, fittings support the complex fluid transport requirements in energy, chemical, construction, and other fields through a combination of standardization and customization.