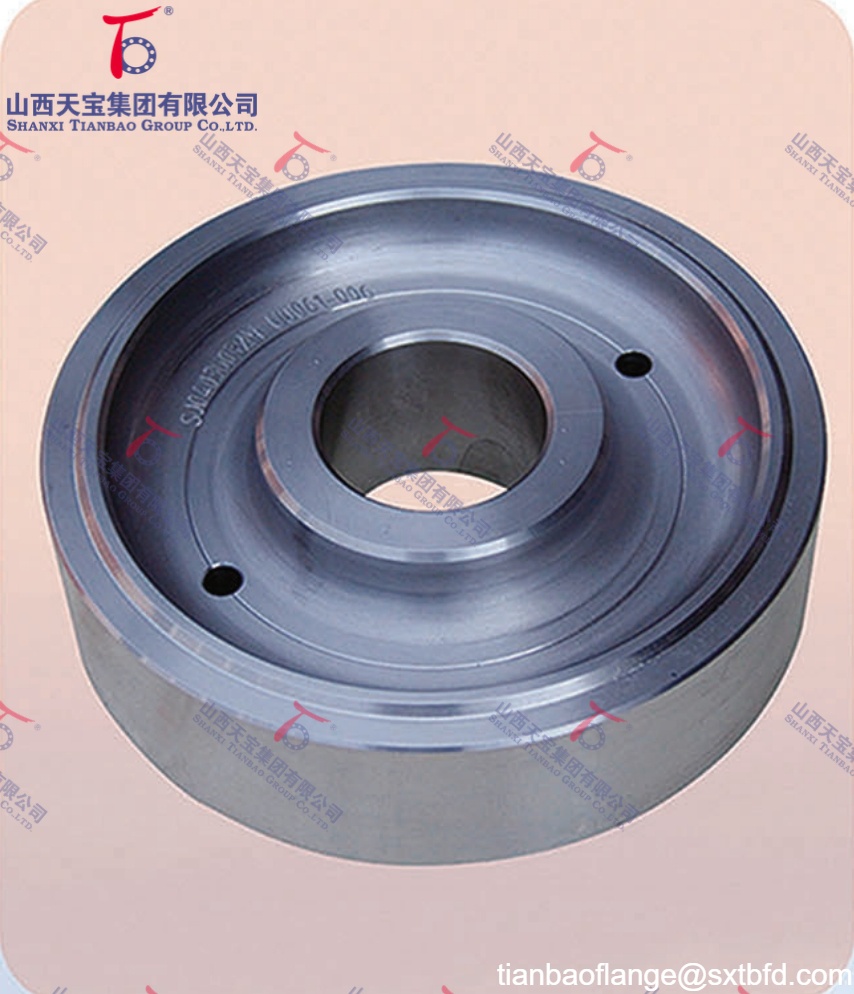

Gears are high-performance transmission mechanical components strengthened through the forging process to enhance metal properties. Composed of a hub, tooth surface, and rim, gears transmit power and motion through the meshing of teeth. They are specifically designed to withstand heavy loads, impacts, and long-term stable operation, making them widely used in industrial fields that demand high reliability and durability.

Gears are made from a variety of materials. Alloy steels such as 42CrMo, 18CrNiMo7-6, and 37SiMn2MoV significantly improve strength, hardenability, and wear resistance through the addition of alloying elements. Case-hardening steels like 20CrMnMo and 16MnCr5 maintain good toughness in the gear core through surface carburizing. Carbon steels such as 35 steel and 45 steel offer good overall performance and lower costs. Stainless steels like 304 and 316 are suitable for corrosive environments.

In general industrial applications, gears operate under pressure ranges from 0.1MPa to 10MPa. For forgings with a design pressure of 1.6 MPa or higher, compliance with Grade II or above standards is typically required. In specialized fields such as aerospace and heavy machinery, gears may need to withstand pressures as high as 50MPa or more, with specific pressure ranges designed according to actual working conditions.

In terms of size, gears are categorized by module into small (0.5 - 5), medium (5 - 20), and large (20 and above), with diameters ranging from a few millimeters to several meters.

Since gears are primarily used for transmitting torque and rotational motion, they generally do not involve specific sealing surface types.