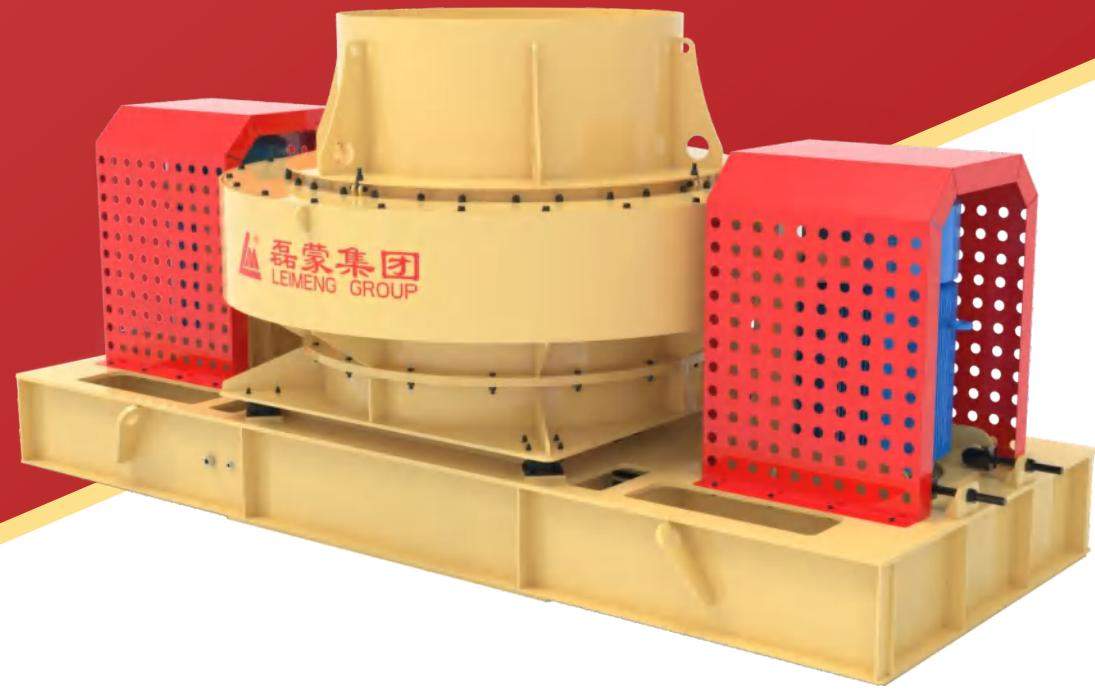

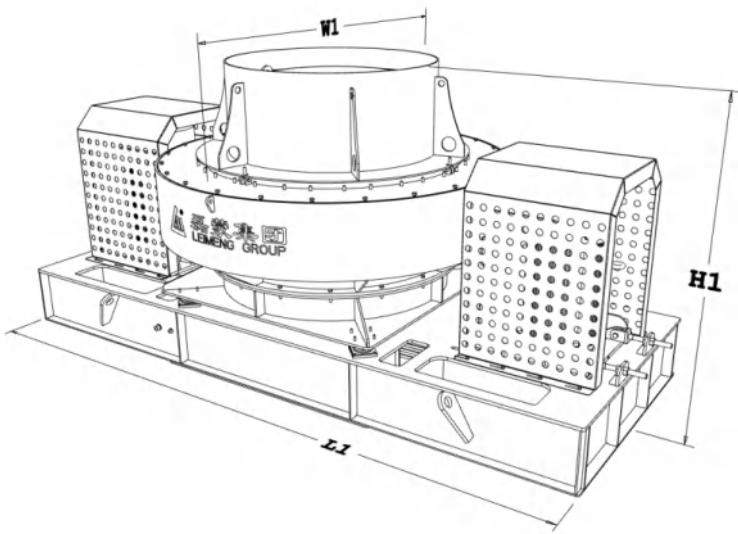

This series of products can select dual-chamber or four-chamber rotors according to actual needs, targeting different materials, functional purposes, and different throughput capacities.

The dual-chamber rotor increases the projection area during material flow. When material passes through the rotor chamber, it achieves higher acceleration, giving the projected material advantages in both projection volume and speed. Alloy tool heads and impact hammers are installed on the outer edge of the rotor chamber, which, in coordination with the anvils in the crushing chamber, form multiple reflections to strike the material repeatedly. It is suitable for sand-making with small particle size materials and, compared to similar products, offers a higher sand-forming rate.

The four-chamber rotor features a reasonable and reliable chamber shape, with multiple projection ports and high throughput. It is used for sand-making and shaping of various materials, allowing free selection of different crushing chambers. Compared to similar products, it achieves greater throughput while providing better shaping effects and a higher sand-forming rate. Its components are affordably priced, resulting in lower operating costs, making it suitable for applications requiring high throughput, particle shape, and sand-forming rate.