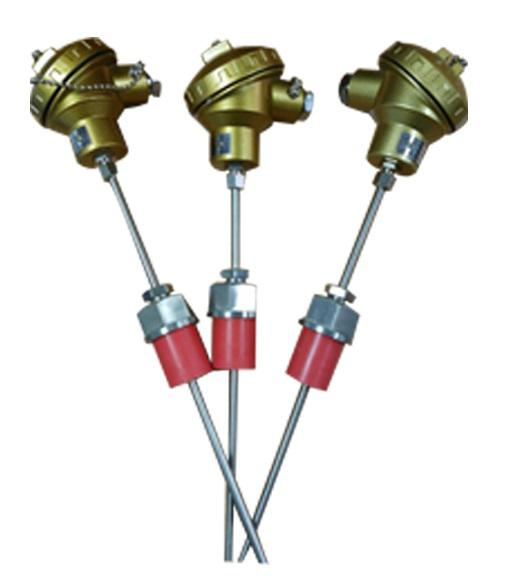

The ZDTC9104/9204 series independent armored thermocouples and resistance temperature detectors feature a design where the sensing element of the armored thermocouple or RTD is directly in contact with the measured medium without the need for an additional protective sheath. This series is typically used in environments with mild conditions, where there is no abrasion, strong corrosion, or other special requirements, and where fast response times are necessary. Since they are fully armored, they offer advantages such as vibration resistance, flexibility, and compact size, making them suitable for confined spaces or areas with moderate vibration.

Main technical indicators:

|

Applicable temperature of different diameter temperature sensing elements: |

||||||

|

Diameter Temperature resistance Indexing number |

Skin material |

Φ0.5Φ1 |

Φ1.5Φ2 |

Φ3Φ4Φ5 |

Φ6Φ8 |

|

|

S |

Long-term temperature resistance (℃) |

GH3030 |

1100 |

|||

|

Instantaneous temperature resistance (℃) |

1200 |

|||||

|

K |

Long-term temperature resistance (℃) |

GH30300Cr25Ni20 |

400 |

700 |

800 |

1000 |

|

Instantaneous temperature resistance (℃) |

500 |

800 |

900 |

1100 |

||

|

K |

Long-term temperature resistance (℃) |

1Cr18Ni9Ti316L |

300 |

500 |

700 |

750 |

|

Instantaneous temperature resistance (℃) |

400 |

600 |

800 |

800 |

||

|

E |

Long-term temperature resistance (℃) |

300 |

400 |

500 |

700 |

|

|

Instantaneous temperature resistance (℃) |

400 |

500 |

600 |

800 |

||

|

J |

Long-term temperature resistance (℃) |

200 |

300 |

400 |

600 |

|

|

Instantaneous temperature resistance (℃) |

300 |

400 |

500 |

700 |

||

|

T |

Long-term temperature resistance (℃) |

150 |

200 |

250 |

300 |

|

|

Instantaneous temperature resistance (℃) |

200 |

300 |

300 |

350 |

||

|

Pt100 |

Long-term temperature resistance (℃) |

450 |

500 |

|||

|

Instantaneous temperature resistance (℃) |

500 |

500 |

||||

|

Cu50 |

Long-term temperature resistance (℃) |

100 |

150 |

|||

|

Instantaneous temperature resistance (℃) |

150 |

150 |

||||

Selection Table of ZDTC9104 Independent Armored Thermal Resistance

|

ZDTC9104 |

Selection code |

Description |

|

Instrument grade |

A B |

High precision, high stability |

|

High stability |

||

|

Structure form |

C1 C2 |

No protection tube |

|

Cold end protection tube |

||

|

Form of junction box |

301 304 305 306 307 308 309 310 311 312 313 314 315 316 |

Spring-loaded junction cold plate type |

|

Cold end joint type |

||

|

Built-in spring type |

||

|

Enhanced cold end type |

||

|

Simple aviation plug type |

||

|

Standard aviation plug type |

||

|

Hirschman connector type |

||

|

Simple Handle |

||

|

Handle type |

||

|

Outlet Splash-proof |

||

|

Export small clamshell |

||

|

KNE type junction box |

||

|

Multi-point aviation plug (2~10 points) |

||

|

Multi-point waterproof junction box (2~6 points) |

||

|

Transformer output signal/corresponding temperature range |

W M/ V/ |

No transmission output |

|

Transmission output 4 ~ 20mA/temperature range |

||

|

Transmission output 1~5V/temperature range |

||

|

Fixed installation form |

W F1 F3 F4 G1 G3 G4 L T1 |

No fixing device |

|

Fixed thread |

||

|

Fixing ferrule thread |

||

|

Movable ferrule thread type |

||

|

Fixed flange |

||

|

Fixed ferrule flange |

||

|

Movable ferrule flange type |

||

|

Right Angle |

||

|

special form |

||

|

Indexing number |

P C |

Pt100 indexing platinum resistance |

|

Cu50 indexing copper resistance |

||

|

Number of components |

1 2 N |

Single-element type |

|

Dual-element type |

||

|

Multipair type (n denotes the number of elements) |

||

|

Core type |

K T |

Regular armored core |

|

Spring-loaded armored core |

||

|

Accuracy Class |

A B |

Industrial Class A |

|

Industrial Class B |

||

|

Material of protection tube |

B M T2 |

1 Cr18Ni9Ti(0~1000 ℃) |

|

316L(0 special form 0~1000 ℃) |

||

|

Special requirements |

||

|

Lead type |

B H F FP |

Rubber conductor (temperature resistance 0~70 ℃) |

|

PVC conductor (temperature resistance 0~75 ℃) |

||

|

PTFE wire (temperature resistance 0~250 ℃) |

||

|

PTFE shielded wire (temperature resistance 0~250 ℃) |

||

|

Diameter of protection tube |

A single-digit number directly indicates the actual diameter, for example, 6 represents φ6 (only for φ3~φ8) |

|

|

Product length |

User specified (full length or full length × insertion depth × lead length) |

|

|

Selection example |

ZDTC9104 A C1 301 W F1 P 1 K A B B |

|

|

Ordering Method |

CDW selection personnel can be ignored |

|

ZDTC9204 Independent Armored Thermocouple Selection Table

|

ZDT9204 |

Selection code |

Description |

|

Instrument grade |

A B |

High precision, high stability |

|

High stability |

||

|

Structure form |

C1 C2 |

No protection tube |

|

cold end protection tube |

||

|

Form of junction box |

301 302 303 304 305 306 307 308 309 310 311 312 313 314 315 316 |

Spring-loaded terminal connection cold-rolled plate type |

|

Flat plug type |

||

|

Simple plug-in type |

||

|

Cold end joint type |

||

|

Built-in spring type |

||

|

Enhanced cold end type |

||

|

Simple aviation plug type |

||

|

Standard aviation plug type |

||

|

Hirschman plug type |

||

|

Simple Handle |

||

|

Handle type |

||

|

Outlet Splash-proof |

||

|

Export small clamshell |

||

|

KNE type junction box |

||

|

Multi-point aviation plug (2~10 points) |

||

|

Multi-point waterproof junction box (2~6 points) |

||

|

Transmission output signal/ Corresponding temperature range |

W M/ V/ |

No transmission output |

|

Transmission output 4 ~ 20mA/temperature range |

||

|

transmission output 1~5V/temperature range |

||

|

Fixed installation form |

W F1 F3 F4 G1 G3 G4 L T1 |

No fixing device |

|

Fixed thread |

||

|

Fixing ferrule thread |

||

|

Movable card sleeve thread |

||

|

Fixed flange |

||

|

Fixed ferrule flange |

||

|

Movable card sleeve flange |

||

|

Right Angle |

||

|

special form |

||

|

indexing number |

T J E |

T-indexing thermocouple |

|

J-indexing thermocouple |

||

|

K-indexing thermocouple |

||

|

Number of components |

1 2 n |

Single-element type |

|

Dual-element type |

||

|

Multipair type (n denotes the number of elements) |

||

|

Accuracy Class |

A B |

Industrial Class A |

|

Industrial Class B |

||

|

Material of protection tube |

B M C G T2 |

1 Cr18Ni9Ti(0~1000 ℃) |

|

316L(0~1000 ℃) |

||

|

Cr25Ni20 (0~1100 ℃) |

||

|

GH3030((0~1200 ℃) |

||

|

Special requirements |

||

|

Lead type |

JP FP |

Metal shield conductor (temperature resistance 0~300 ℃) |

|

PTFE shielded wire (temperature resistance 0~250 ℃) |

||

|

Diameter of protection tube |

A single-digit number directly represents the actual diameter, for example, 6 represents φ6 (limited to φ3~φ8) |

|

|

Selection example |

ZDTC9204 A C1301 W F1 T 1 A B JP |

|

|

Ordering Method |

C D W he selection personnel can be ignored |

|