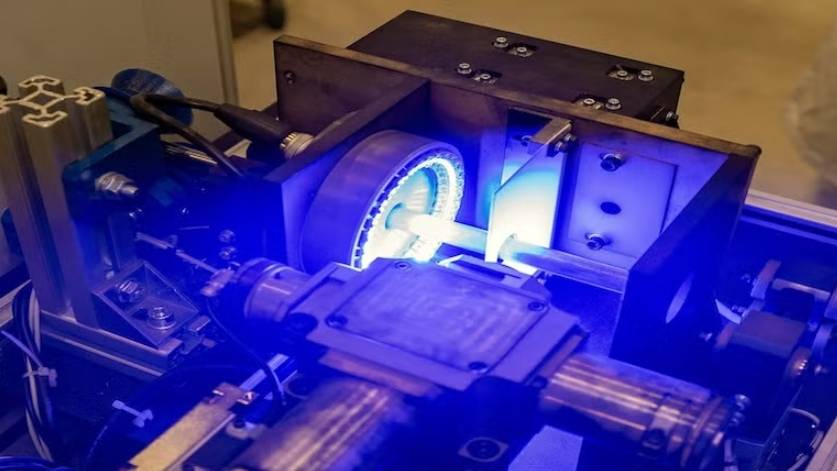

Wedoany.com Report-Apr. 19, The Chepetsk Mechanical Plant (ChMZ) in Russia’s Udmurt Republic, a part of Rosatom’s Fuel Division, has implemented an advanced automated system utilizing neural networks to inspect zirconium shells for RBMK reactors. This technology ensures high-quality standards for nuclear fuel components.

The system employs video monitoring at 150 frames per second to capture images of zirconium shells and identify potential defects. Neural network algorithms analyze these images against a comprehensive database containing thousands of defect images, compiled over several years of training. When a defect is detected, the shell is examined by an automated electronic microscope using interferometry to measure defect depth or height with precision, comparing results to acceptable standards. Additionally, shadow optoelectronic sensors assess the shell’s straightness, ensuring overall quality of the pipe’s outer surface.

Developed specifically for ChMZ by the Siberian Branch of the Russian Academy of Sciences in Novosibirsk, the system’s control infrastructure was designed and produced by Pribor-Service, a subsidiary of the plant. This collaboration highlights the integration of advanced technology to enhance manufacturing precision.

Sergey Chineykin, General Director of ChMZ, stated: “Neural networks combined with high-resolution optical systems will completely eliminate the influence of the subjective human factor when evaluating the appearance of products.” He added: “Automated control is another step towards the perfect quality of zirconium shells, which, in turn, guarantees the reliability of Russian fuel for nuclear power plants. Our plans are to introduce similar quality control technologies not only into the production of RBMK fuel shells, but also into the manufacturing process of products for all other types of reactors produced by our plant.”

The introduction of this automated complex marks a significant advancement in quality assurance at ChMZ. By leveraging neural networks and high-precision optical systems, the plant minimizes human error and enhances the reliability of its products. The technology ensures that zirconium shells meet stringent quality requirements, contributing to the safety and efficiency of nuclear power generation.

ChMZ aims to expand the application of these quality control technologies across its production lines, covering components for various reactor types. This initiative reflects the plant’s commitment to innovation and excellence in manufacturing, supporting the broader goal of delivering dependable nuclear fuel components for global energy needs.