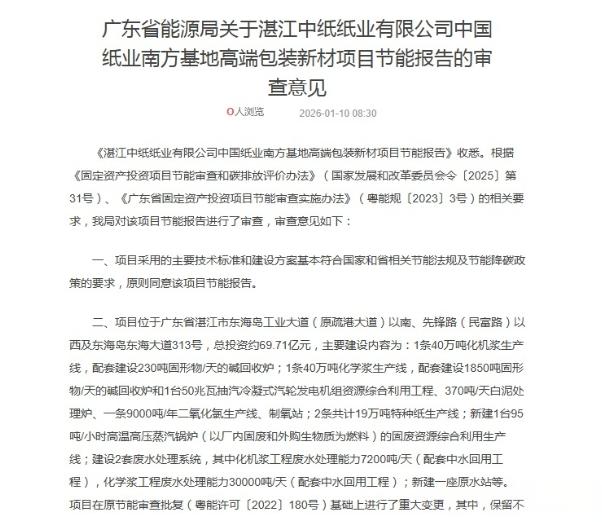

Wedoany.com Report on Feb 7th, Recently, the Guangdong Provincial Development and Reform Commission issued the "Guangdong Provincial Energy Bureau's Review Comments on the Energy Conservation Report for the China Paper Southern Base High-End Packaging New Materials Project of Zhanjiang Zhongzhi Paper Co., Ltd." The main technical standards and construction plan adopted for the project basically comply with the requirements of national and provincial energy conservation regulations, as well as energy-saving and carbon reduction policies. In principle, the energy conservation report for the project has been approved.

The announcement shows that the project is located south of Donghai Island Industrial Avenue (formerly Shugang Avenue) and west of Xianfeng Road (Minfu Road) in Zhanjiang City, Guangdong Province, with the specific address at No. 313 Donghai Avenue, Donghai Island. The total investment is approximately 6.971 billion yuan.

Main Construction Content:

One 400,000-ton chemi-mechanical pulp production line, with supporting construction of a 230-ton solids/day alkali recovery boiler;

One 400,000-ton chemical pulp production line, with supporting construction of a 1,850-ton solids/day alkali recovery boiler, one 50 MW extraction condensing steam turbine generator set for comprehensive resource utilization, a 370-ton/day lime mud processing kiln, one 9,000-ton/year chlorine dioxide production line, and an oxygen generation station;

Two specialty paper production lines with a total capacity of 190,000 tons;

A new comprehensive solid waste resource utilization production line with one 95-ton/hour high-temperature and high-pressure steam boiler (fueled by in-plant solid waste and purchased biomass);

Construction of two wastewater treatment systems, including a wastewater treatment capacity of 7,200 tons/day for the chemi-mechanical pulp project (with supporting reclaimed water reuse project) and 30,000 tons/day for the chemical pulp project (with supporting reclaimed water reuse project);

Construction of a new raw water station, etc.

The project underwent significant changes compared to the original energy conservation review approval (Yueneng Permit [2022] No. 180). Among them, the unchanged 400,000-ton chemi-mechanical pulp project has already commenced full-scale construction in July 2024 and is expected to be fully completed by June 2026. The construction schedule for other components is as follows: the 400,000-ton chemical pulp project is planned to start construction in July 2026 and is expected to be fully completed by July 2028; the 190,000-ton specialty paper project is planned to commence construction in July 2027 and begin operation in December 2028; the comprehensive solid waste resource utilization project is planned to start construction in January 2027 and be completed and operational by April 2028.

Energy-Consuming Processes:

The chemi-mechanical pulp production line adopts the P-RC APMP process. High-concentration wastewater is sent to alkali recovery after MVR and forced circulation evaporation. The main production process steps include chip washing, pre-impregnation (alkaline hydrogen peroxide treatment), high-concentration refining (30%-40% consistency), medium and high-concentration bleaching, multi-stage washing, and screening, etc.;

The chemical pulp production line adopts low-solids continuous cooking and four-stage ECF medium-concentration bleaching processes. Steam generated by the recovery boiler is utilized for waste heat power generation with a 50 MW unit. Main process steps include chip pre-impregnation (or steaming), continuous cooking (cold blow technology), counter-current washing, pressure screening, oxygen delignification, and four-stage bleaching (D0-EO-D1-D2);

The specialty paper machine production line employs advanced domestic and international equipment, control systems, and new energy-saving processes and technologies. The production line adopts an integrated short-process efficient papermaking process, including process steps such as stock preparation, short-process deaeration, shoe press, drying, heat pump systems, and heat recovery from enclosed hoods. The core involves using a turbine vacuum system to replace water-ring vacuum pumps and optimizing the heat network of the drying section to achieve cascade utilization of waste heat;

Comprehensive solid waste resource utilization project: Utilizes a "high-temperature and high-pressure boiler" (10.5 MPa, 515°C). By co-firing biomass, it achieves reuse of the calorific value of solid waste fuels such as in-plant sludge, pulp residues, and wood chips. A sludge drying scheme is implemented to fully utilize flue gas waste heat;

The chlorine dioxide preparation process adopts an integrated chlorine dioxide generation system.

Energy-Consuming Equipment:

(I) Main Equipment: 2 MSD600 chip compression shredders (power 3300 kW, energy efficiency level 2), NBKP refiners (5 units: power 315 kW, 5 units: power 400 kW, energy efficiency level 1), LBKP refiners (4 units: power 630 kW, energy efficiency level 1), 5 X60 pressure screens (power 315 kW, energy efficiency level 2), MVR evaporators (4 sets: total compressor fan power 12000 kW, energy efficiency level 2; total circulation pump power 1056 kW, energy efficiency level 2), continuous digester (with cold blow technology), shoe press bottom roll drive points (2 units: power 600 kW; 2 units: power 500 kW), 1850-ton solids/day alkali recovery boiler (alkali recovery rate: 98%, rated evaporation capacity: 286 tons/hour), 230-ton solids/day alkali recovery boiler (alkali recovery rate: 98%), 370-ton/day lime mud processing kiln (natural gas consumption per ton of pulp: 46 standard cubic meters/ton), and other equipment.

(II) Auxiliary Equipment: 1 high-temperature and high-pressure solid waste boiler (rated evaporation capacity: 95 tons/hour, thermal efficiency: 87.5%, main steam parameters: 10.5 MPa, 515°C), 1×50 MW extraction condensing steam turbine generator set; induced draft fans (5 units, energy efficiency level 1; 2 units, energy efficiency level 2), primary air fans (2 units, energy efficiency level 1), secondary air fans (2 units, energy efficiency level 1), feedwater pumps (5 units, energy efficiency level 1), chilled water pumps (4 units, energy efficiency level 1), circulation pumps (5 units, energy efficiency level 1); 3 air-cooled screw air compressors (energy efficiency level 2), 3 air-cooled screw air compressors (energy efficiency level 1); 2 water-cooled screw chillers (energy efficiency level 2), as well as auxiliary equipment such as fans, pumps, lighting, and environmental treatment facilities.