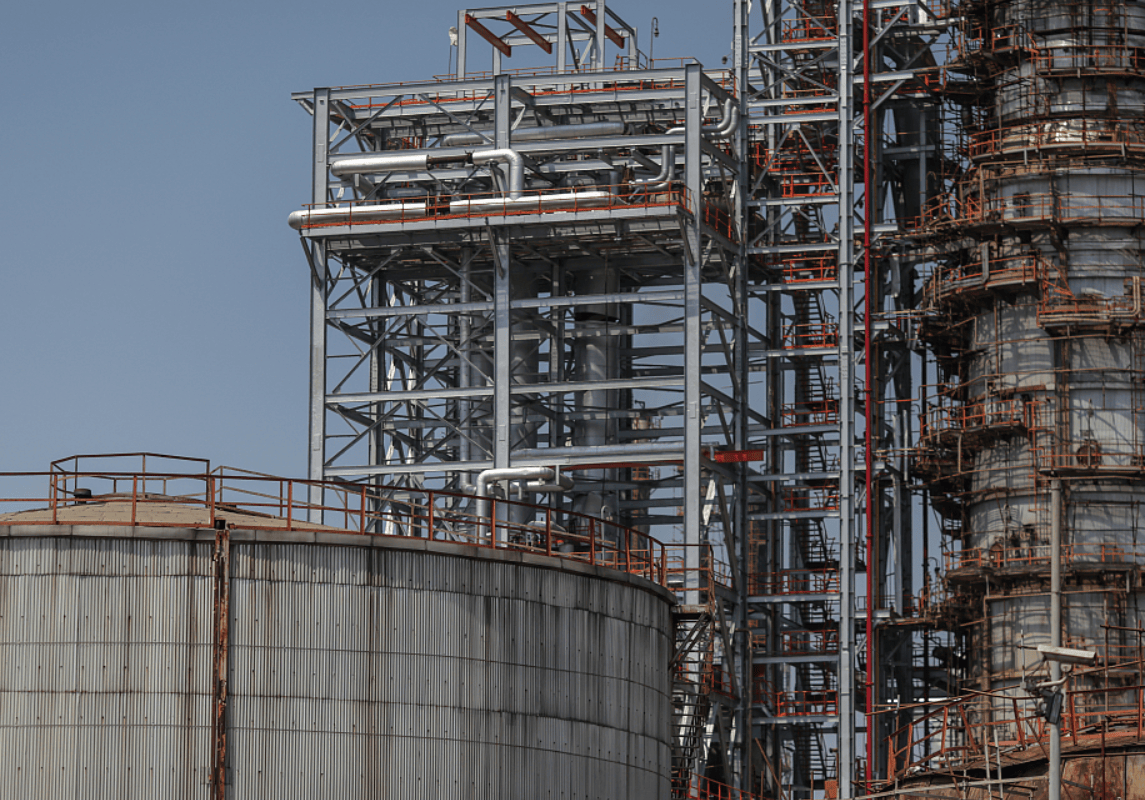

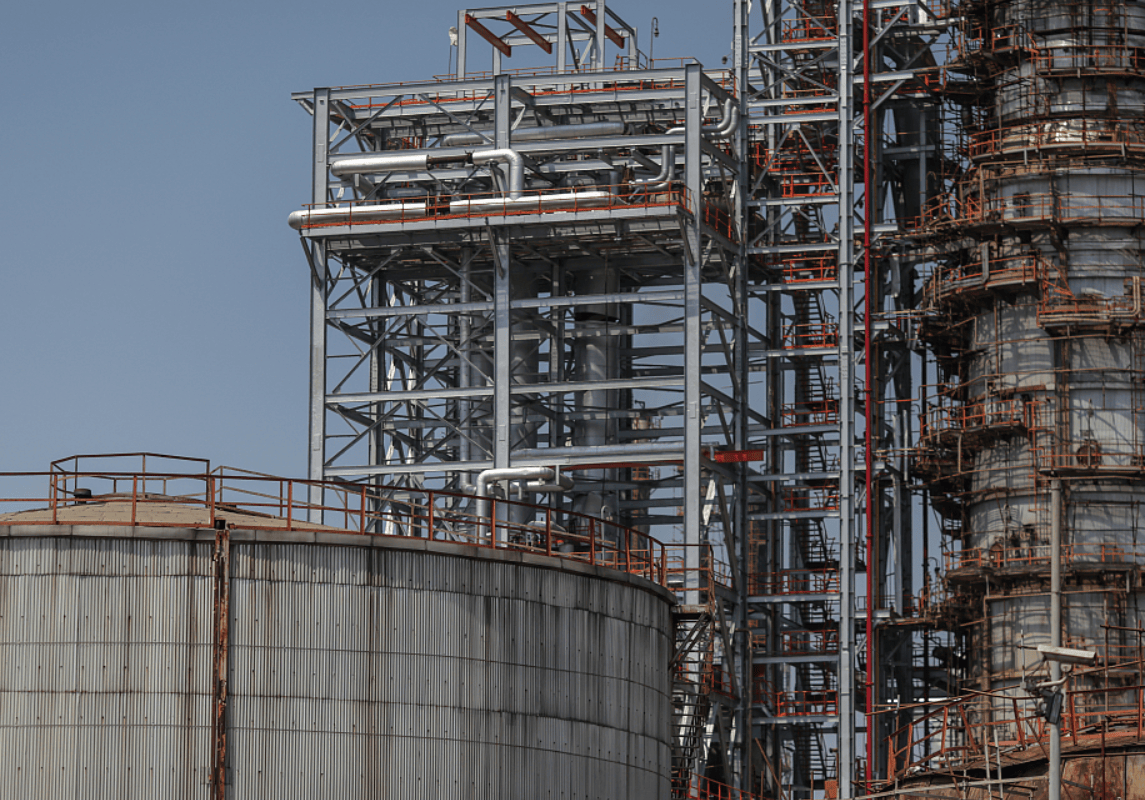

Wedoany.com Report on Feb 15th, Bharat Petroleum Corporation Limited (BPCL) of India has announced a major investment plan, intending to invest approximately 490 billion rupees to develop an integrated refinery and petrochemical park near the Bina Refinery in Madhya Pradesh. This project is seen as a significant move in India's downstream investment sector, reflecting BPCL's strategic shift towards high-value petrochemical production and backward integration.

According to the plan, BPCL will increase the capacity of the Bina Refinery from 7.8 million metric tons per year to 11 million metric tons per year and integrate an ethylene cracker with an annual capacity of 1.2 million metric tons as the core for polymer and petrochemical production. This dual strategy enables the company to convert more crude oil into high-value chemicals rather than just transportation fuels, thereby improving profitability and operational efficiency.

BPCL is adopting a globally proven integrated refinery-petrochemical model, similar to those of Saudi Aramco and ExxonMobil. Under this model, the refinery and petrochemical units share utilities, feedstock streams, and infrastructure, which helps reduce capital costs and enhance overall efficiency, maximizing asset utilization while lowering operational expenses.

To fund this petrochemical complex project, BPCL expects to combine internal accruals, debt financing, and possible government support. The specific funding structure will be determined based on official disclosures and investor guidance. The annual ethylene production capacity of 1.2 million metric tons will position BPCL as a key supplier in India's expanding petrochemical market. Industry trends indicate an 8-10% annual growth in ethylene demand, driven by consumption in packaging, automotive, and construction sectors. Increasing domestic production will help reduce India's reliance on imports.

The petrochemical complex will target several high-growth polymer markets, including polyethylene (with demand growing 12-15% annually and high import volumes), polypropylene (supported by automotive and packaging applications), and specialty polymers (driven by diversification in industry and manufacturing). Through backward integration, BPCL can control feedstock costs, ensure a consistent supply, and reduce risks associated with the volatile commercial ethylene market.

BPCL plans to develop the complex in phases, initially utilizing 40-50 acres of land with flexibility for expansion. Industry estimates suggest the area could accommodate 8-12 downstream manufacturing units, potentially evolving into a larger petrochemical and manufacturing hub in the long term. To support operations, BPCL will build robust infrastructure, including integrated utilities, water treatment systems, power distribution, waste management facilities, and logistics connectivity, ensuring smooth, efficient operation of downstream units and compliance with environmental requirements.