UK battery pack manufacturer Alexander Battery Technologies (ABT) has released a new OEM battery development framework, providing clearer guidance for enterprises tackling battery design and manufacturing. This framework defines four distinct development pathways, helping companies make choices based on constraints such as cost, delivery timelines, and technical risk, thereby optimizing the management of battery projects.

In fields such as drones, robotics, and medical devices, enterprises often face pressure to transition rapidly from prototypes to production while needing to balance compliance, cost, and supply stability. Battery projects are typically not uniform, often falling between off-the-shelf solutions and full customization, which can lead to uncertainty regarding project scope, timelines, and expectations. The new framework aims to address these issues by clarifying upfront the implications for flexibility, delivery, and investment.

Mark Rutherford, CEO of Alexander Battery Technologies, stated: "OEM battery development projects almost never follow a single, linear path. Some teams need to rapidly advance a proven design, others need to adapt as the product evolves, and many are managing new developments alongside existing platforms. Treating all projects as a single type creates friction and delays. We observed a need for clearer decision points earlier in this process. Defining these pathways enables engineering and procurement teams to understand the impact of their choices on cost, compliance, and schedules before making commitments."

The service structure includes using mature battery architectures with limited modifications, fully end-to-end custom development, and manufacturing to existing designs. All design-led projects standardly include UN38.3 testing, with additional regulatory support provided as needed. Manufacturing-to-print projects can achieve rapid turnaround within weeks, depending on material lead times.

Enterprises can also operate multiple pathways concurrently, such as combining manufacturing-to-print for existing products with the development of new custom battery packs, allowing for shared tooling or components where appropriate to enhance efficiency.

Mr. Rutherford added: "The challenge of OEM battery development is not just designing a battery, but designing a project that can be delivered and scaled over time. Clarifying pathway decisions from the outset helps teams manage regulatory requirements, make practical engineering and procurement decisions, and avoid unnecessary rework as the product moves towards production."

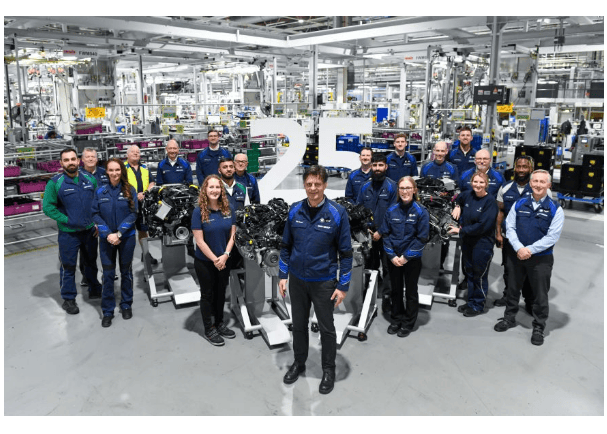

This framework targets enterprises developing battery-powered products, covering industries such as drones, robotics, power tools, and medical devices. All services are delivered through ABT's UK-based manufacturing facilities, supported by a global supply chain, providing a comprehensive solution for OEM battery development.