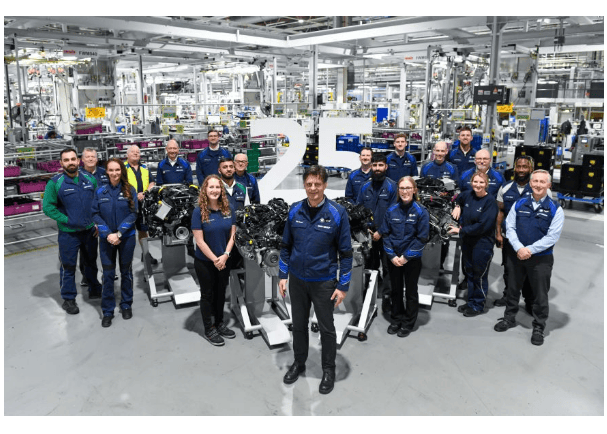

The BMW Group's UK engine production base, the Hams Hall plant located in North Warwickshire, recently celebrated its 25th anniversary. Since commencing production in 2001, the plant has cumulatively manufactured over 7.6 million engines and engaged in high-precision machining of critical components. As a key part of the BMW Group's global technology layout, the Hams Hall plant supplies the latest generation of efficient petrol engines to several of the Group's production bases worldwide, including powertrain units for plug-in hybrid models.

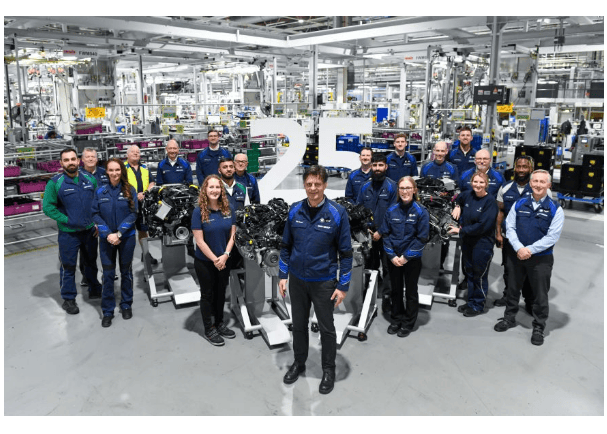

Currently, the engine product line at the Hams Hall plant includes three-cylinder and four-cylinder petrol engines, as well as high-performance V8 engines, primarily used in BMW and Mini brand vehicles. The V12 engines are exclusively custom-produced for Rolls-Royce Motor Cars. Their assembly process employs a unique, bespoke workflow carried out by specially trained employees, with final delivery to the Rolls-Royce factory in Goodwood. Plant Director Dirk Dreher stated: "This anniversary is a special milestone for us. We have a competitive team, and our employees continuously optimize manufacturing processes with passion. Building on a solid foundation, we look forward to maintaining our success in the future."

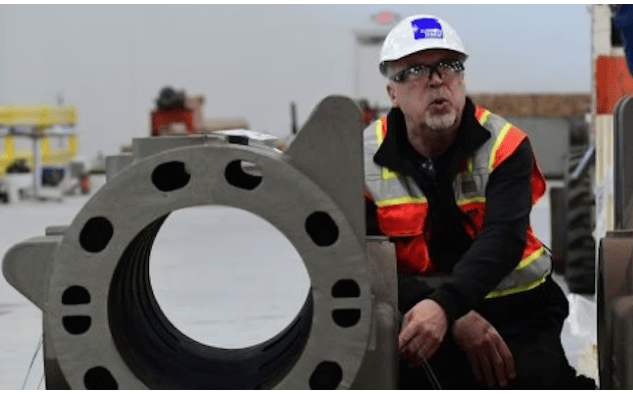

Over its 25-year development journey, the Hams Hall plant has demonstrated significant growth. Starting with the production of just one engine series, it has now expanded to two different series, with the recent integration of V8 and V12 engines enhancing its commercial value. The high-precision machining business has also achieved a leap, with capacity tripling over the past decade. Annual output now exceeds 1 million components, and the supply scope has extended to the BMW Group's Steyr plant in Austria. Engine Production Director Harald Gottsche pointed out: "The Hams Hall plant is a crucial part of our global production network. It combines technical expertise with high flexibility, reliably providing efficient, high-quality engines, including the masterpiece that is the V12."

As the 25th anniversary arrives, the Hams Hall plant is applying the BMW iFactory manufacturing principles, focusing on efficient, sustainable, and digital production. The plant has long emphasized sustainability. Since its first full production year, energy consumption per engine has been reduced by 61%, total energy consumption has remained stable, and all external electricity is sourced from renewable energy. Regarding digitalization, the plant has established a fully connected digital twin system, comprising 3D models, data layers, and application layers, providing a real-time operational view. Autonomous robot dogs and robots assist with maintenance and production, while AI camera technology enhances quality inspection efficiency.

The Hams Hall plant also fosters a culture of continuous improvement. Through employee initiatives such as "Think Innovation," it reduces waste and saves costs. These efforts ensure the plant's leading position in the field of engine production and lay a foundation for future growth.