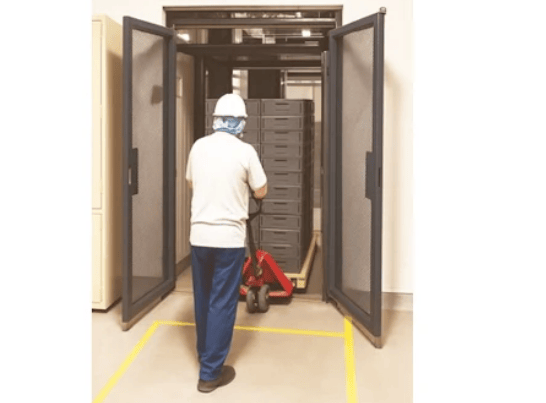

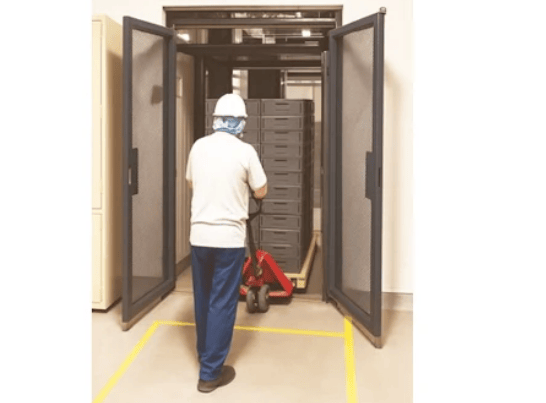

Wedoany.com Report on Feb 14th, PFlow Industries (based in Milwaukee, Wisconsin) has introduced vertical reciprocating conveyors suitable for food facilities, including the M-Series and F-Series models. Through food-grade design and robust construction, these devices provide reliable vertical lifting solutions for food manufacturers, helping to enhance operational efficiency, ensure safety, and promote business growth in a competitive market.

Vertical reciprocating conveyors feature hygienic, washable surface finishes, supporting food-safe operations. They can seamlessly integrate with automated conveying systems and material handling equipment, reducing manual intervention, lowering contamination risks, and maintaining efficient production flow. This durable infrastructure helps streamline compliance processes, reduce forklift usage, eliminate cross-contamination hazards, and maintain sanitary workflows crucial for safe and efficient food manufacturing and packaging.

The M-Series dual-mast mechanical material lift can handle loads up to 10,000 pounds and is available in straddle or cantilever configurations. Designed for high-speed, high-cycle environments, it offers excellent safety performance, efficient multi-level load transfer capability, and compatibility with advanced automation systems. Its robust construction reduces manual handling, eliminates cross-contamination points, and enhances production efficiency in demanding food processing and packaging applications.

The F-Series vertical reciprocating conveyor is designed to meet the needs of large-scale food manufacturing environments, offering powerful performance and flexible platform sizes and loading channels. With a standard capacity of 50,000 pounds, it can be customized to handle loads exceeding 200,000 pounds as needed, with virtually unlimited platform size options. The F-Series is suitable for oversized loads, bulk materials, and high-volume palletized transport in multi-level indoor or outdoor environments. Four-sided loading/unloading, advanced wash-down or corrosion-resistant finishes, and flexible traffic patterns make it an ideal choice for food manufacturing applications with high demands on size, speed, and hygienic design.

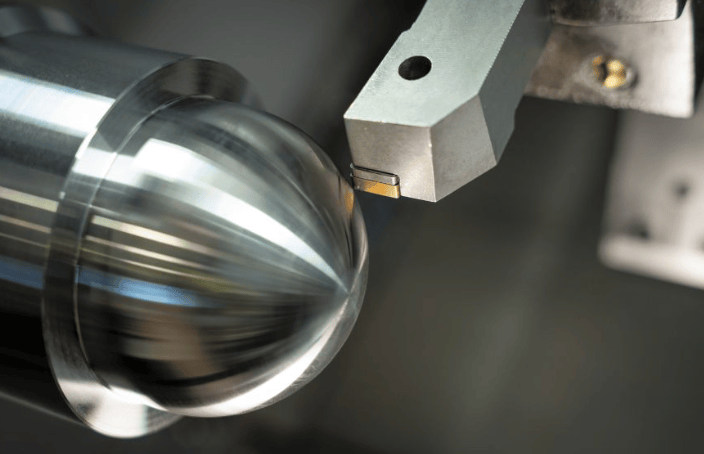

Vertical reciprocating conveyors are not just standalone equipment but integrated, permanent infrastructure that provides long-term operational resilience as part of facility design. Built with advanced materials and corrosion-resistant surface treatments, these conveyors can withstand the frequent cleaning, chemical exposure, and wash-down conditions common in food and beverage processing/manufacturing environments.