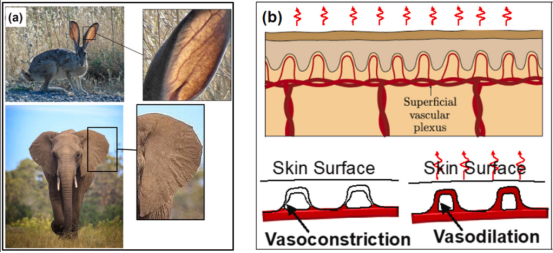

Researchers at Drexel University have drawn inspiration from the venous ears of fennec foxes and elephants to propose a new passive heating and cooling method that could improve energy efficiency in future buildings. The concept was recently published in the Journal of Building Engineering, involving the embedding of vascular networks in cement-based building materials filled with paraffin-based substances to passively regulate the temperature of walls, floors, and ceilings.

Buildings account for nearly 40% of global energy consumption, contributing significantly to greenhouse gas emissions, with roughly half of that energy used to maintain comfortable indoor temperatures. While new insulation products and technologies help reinforce building envelopes, heat gain or loss through surfaces remains the biggest challenge, accounting for about 63% of a building's energy loss. Undergraduate engineering student and co-author Rhythm Osan noted that from an architectural perspective, windows are aesthetically pleasing windows reduce insulation performance, and in reality, buildings always lose heat due to various issues.

The Drexel team designed a method to make building surfaces actively help maintain indoor temperature. Associate Professor and lead researcher Amir Farnam from the College of Engineering stated that the human circulatory system is highly effective at regulating body temperature, and they aim to replicate this process in building materials.

Farnam's Advanced Infrastructure Materials (AIM) Lab leads in using natural methods to improve infrastructure material durability, having previously developed phase-change-material concrete that melts surface ice and snow, self-healing concrete using special bacteria, and 3D-printed polymers for concrete reinforcement.

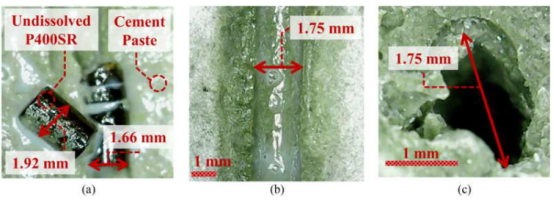

To create thermally responsive building materials, the team drew inspiration from multiple attempts, using printed polymer matrices to create channel networks on concrete surfaces, then filling them with paraffin-based substances. Phase-change materials like paraffin absorb and release thermal energy during transitions between liquid and solid states—releasing heat when solidifying as temperature drops and absorbing heat when melting as temperature rises, cooling the surface. AIM Lab research scientist and co-author Robin Deb noted that they had previously used paraffin-based materials for self-heating concrete; for this study, they selected a phase-change material with a melting point of about 18°C to test effectiveness in cold climates. The system can also be customized for warmer climates.

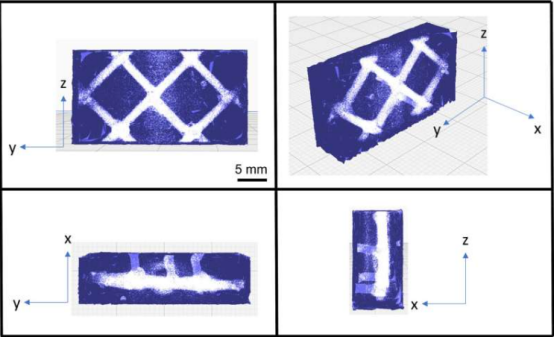

The team created a series of cement samples with varying vascular channel patterns using dissolvable or "sacrificial" polymer templates—including single-channel, multi-channel, and other configurations with thicknesses from 3 to 8mm. They tested each sample for mechanical behavior and the ability to slow surface warming and cooling when channels were filled with phase-change material.

Results showed that samples with a diamond-grid channel structure combined strength and thermal regulation most effectively, maintaining structural integrity under tensile and compressive tests while slowing surface heating and cooling rates (1–1.25°C per hour). Deb noted that larger vascular surface area yields better thermal performance, similar to the physiology of elephant and fennec fox ears.

To enhance material strength, the team demonstrated that adding fine aggregate to the cement improves durability without affecting the vascular system's ability to circulate phase-change material.

Farnam stated that while the study aimed to validate the concept, the results are promising—not only proving the method effective for regulating the surface temperature of cement-based materials but also showing it to be a simple and cost-effective manufacturing approach with potential to make a major contribution to improving building energy efficiency. In the future, the team will test different phase-change materials and channel configurations in larger cement samples under longer durations and wider environmental temperature ranges.