Wedoany.com Report-Oct. 1, Japanese researchers have developed a solid hydrogen battery that operates at 90 °C, achieving reversible hydrogen gas absorption and release. The battery uses magnesium hydride (MgH₂) as the anode and hydrogen gas (H₂) as the cathode, with a solid electrolyte, Ba₀.₅Ca₀.₃₅Na₀.₁₅H₁.₈₅, capable of transporting hydrogen ions. “This material has an anti-α-AgI-type crystal structure, well known for its superionic conductivity. In this structure, barium, calcium, and sodium occupy body-centered positions, while H⁻ ions move through face-sharing tetrahedral and octahedral sites, allowing them to migrate freely,” said the Institute of Science Tokyo. During charging, MgH₂ releases H⁻ ions, which migrate through the electrolyte to the H₂ electrode, where they are oxidized to release H₂ gas. During discharging, H₂ gas at the cathode is reduced to H⁻, which move back to the anode and react with Mg to form MgH₂. Researchers noted that this battery overcomes the high-temperature and low-capacity limits of earlier methods. Their paper, High-capacity, reversible hydrogen storage using H⁻-conducting solid electrolytes, was published in Science.

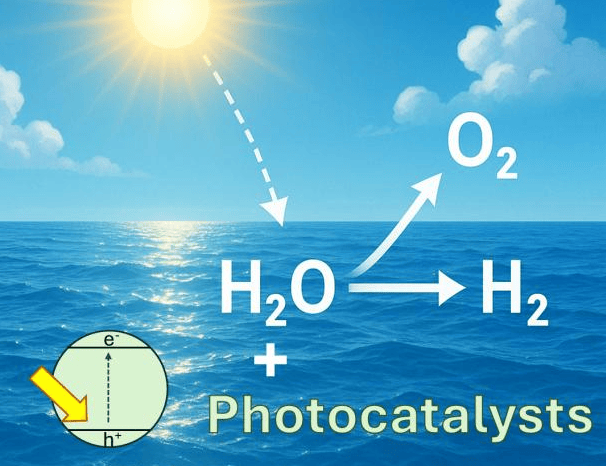

In South Korea, Chung-Ang University researchers proposed chloride-resistant ruthenium (Ru)-based nanocatalysts for direct seawater electrolysis. “The crystalline/amorphous Ru heterostructure exhibits 37× higher activity than commercial Pt catalysts in alkaline water electrolysis, enabling cost-effective hydrogen generation,” said the team led by Haeseong Jang. They used a g-C₃N₄-mediated pyrolysis strategy to synthesize nitrogen-doped carbon-supported Ru nanoclusters with a crystalline–amorphous heterostructure (a/c-Ru@NC). g-C₃N₄ acts as both a nitrogen source and scaffold that anchors Ru³⁺ ions. During pyrolysis, reductive gases from g-C₃N₄ reduce Ru³⁺ to metallic Ru nanoparticles while Ru–N bonding forms an amorphous Ru phase.

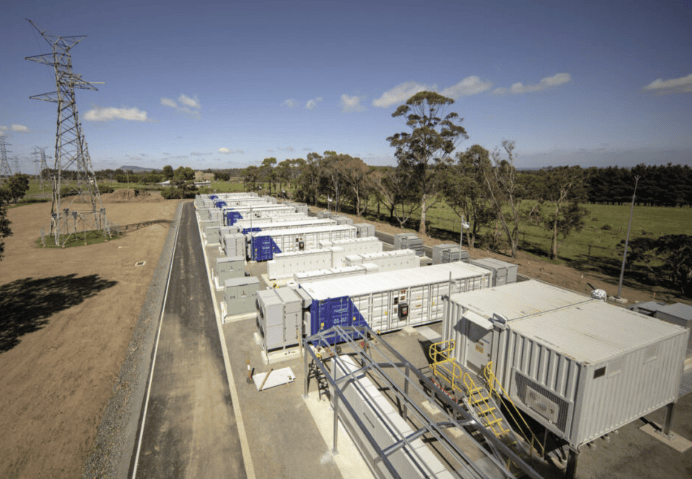

Estonia’s Elcogen officially opened a 14,000 m² solid oxide fuel cell (SOFC) factory on the outskirts of Tallinn, increasing production capacity from 10 MW to 360 MW. “Elcogen's components – cells, stacks, and modules – are integrated into third-party systems for applications including distributed energy, off-grid and stationary power, industrial backup, green hydrogen production, and Power-to-X solutions,” said the company.

In Thailand, the Electricity Generating Authority of Thailand (EGAT) and Chulalongkorn University signed a research fund agreement to explore hydrogen production from renewable energy. “The collaboration aims to promote development focused on the environment, society, and governance guided by international standards, while translating these principles into practical applications,” said EGAT.

Germany’s August Weckermann commissioned a new hydrogen plant at its Eisenbach site, featuring a 300 kW electrolysis unit, hydrogen storage of 1.4 tonnes, and a fuel cell with up to 200 kW output. The plant is integrated with photovoltaics and a redox flow battery with 3,000 kWh storage capacity. “The goal is to achieve a degree of self-sufficiency of up to 85 percent,” said Bernard Gruppe, responsible for process engineering planning.

These developments across Japan, South Korea, Estonia, Thailand, and Germany highlight global progress in hydrogen technologies, spanning advanced storage, seawater electrolysis, large-scale fuel cells, renewable integration, and energy self-sufficiency.