Wedoany.com Report-Nov. 7, Cinis Fertilizer has announced a temporary production halt at its Köpmanholmen, Sweden facility in November to carry out a comprehensive plant overhaul. The pause will allow the company to implement technical improvements aimed at enhancing production capacity and stability amid challenging market conditions.

The company is currently focused on three priorities: lowering the cost of purchased raw materials, boosting the capacity and reliability of potassium sulfate production, and improving finished goods pricing. Recent market conditions, including weak demand and falling product prices alongside rising raw material costs, have negatively affected profitability, making the upgrade timely.

The planned shutdown, starting in mid-November, is expected to last 4–6 weeks to accommodate more extensive technical installations. Key improvements include enhancing the cooling system to stabilize production and increase output, and installing a new filter system to reduce dust emissions, improving workplace safety and environmental compliance.

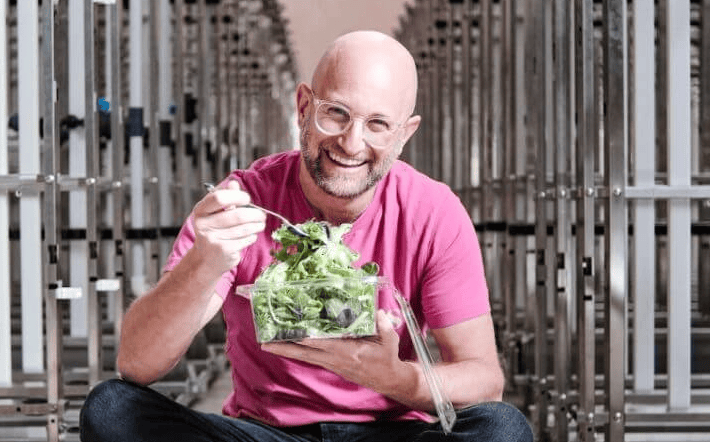

Jakob Liedberg, CEO and founder of Cinis Fertilizer AB, said: “This is good timing to conduct plant improvements given the seasonality of the fertilizer market. A short stop of production provides an opportunity for us to concentrate on implementing planned improvement measures with our own staff and external parties. This overhaul has been carefully planned in order to ensure minimum disruption in the supply of our product.”

The company emphasized that the maintenance program is intended to strengthen long-term operational efficiency while mitigating the effects of market fluctuations. By combining internal expertise with external support, Cinis Fertilizer aims to complete the upgrades effectively, ensuring production can resume at higher capacity and with improved stability.

This strategic investment in technical enhancements is expected to position Cinis Fertilizer for improved performance in the coming months, helping the company better respond to market demand and cost pressures while maintaining product quality.

The plant’s temporary halt is being scheduled to minimize impact on supply chains, with the company confident that its planned measures will result in long-term benefits for both production efficiency and environmental standards.