Wedoany.com Report-Nov. 16, LyondellBasell Industries B.V. (LYB), headquartered in Rotterdam, the Netherlands, has announced the installation of a new Colines cast film line at its Cincinnati Technology Center in the United States. This new addition marks a significant advancement in the company’s research and development capabilities, enabling engineers to create and test high-performance cast film grades under near-commercial conditions.

The Colines cast film line

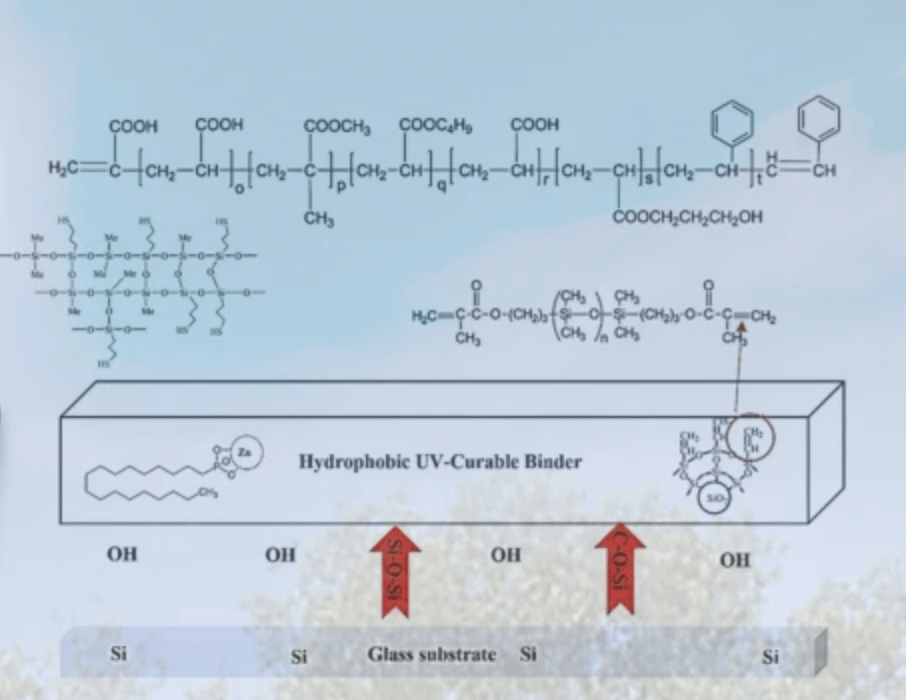

The Colines cast film line has been installed to support the development of advanced stretch films and other specialized applications. It features a 7-layer, 5-extruder configuration designed to closely replicate full-scale industrial production while minimizing material output. The system supports the production of stretch film grades such as Petrothene GA1820 and GA1832, using a chill roll diameter equivalent to that of commercial-scale lines. Each production cycle generates one finished roll, allowing precise quality and performance evaluation.

In addition to stretch film applications, the line offers extensive flexibility for research and testing. It is equipped with interchangeable extruder screws and advanced processing systems capable of producing complex multi-layer structures, including ethylene vinyl alcohol oxygen barrier films with Plexar tie layers. The setup also includes a dual-sided corona treater for downstream lamination or printing, expanding potential uses in areas such as food packaging, medical materials, and industrial products.

The equipment supports film thicknesses ranging from 4 mils (102 microns) to 10 microns (0.4 mils), with a maximum production rate of approximately 1,300 lbs per hour. It is fitted with the same high-speed winder used in commercial operations, ensuring consistent film handling and winding performance comparable to large-scale production facilities.

Mick Hundley, Site Director of the Cincinnati Technology Center, said: “This new cast film line is a testament to our unwavering commitment to innovation and collaboration. By enhancing our capabilities, we are better positioned to collaborate with our customers and deliver tailored solutions that meet their unique needs.”

The investment allows LYB to test complete film structures and optimize designs for improved efficiency and performance. While its configuration for high-speed stretch film production represents a major step forward, the system’s adaptability opens new possibilities for custom film development.

Matt Sonnycalb, AD&TS/PAD Technical Manager, said: “This capability enables LYB to act as a solutions provider more effectively with customers. We now have enhanced the ability to collaborate on structure design and tailor products and solutions to meet unique needs and solve challenges.”

The installation of the Colines cast film line reinforces LYB’s position as a leader in material science and innovation. It strengthens the company’s ability to support customers in developing advanced film solutions across industries while driving progress in sustainable and high-performance manufacturing technologies.