Wedoany.com Report on Feb 3rd, The warehousing industry is currently facing multiple pressures, driving automation technology from an optional solution to a necessity. Labor shortages, rising space costs, and operational complexity are the main challenges. Ben Ferrell, Senior Director at Dematic, points out: "Labor shortages are prompting operators to reduce reliance on manual processes and automate repetitive tasks." Automated warehousing systems can provide stable performance and reduce the impact of staff turnover.

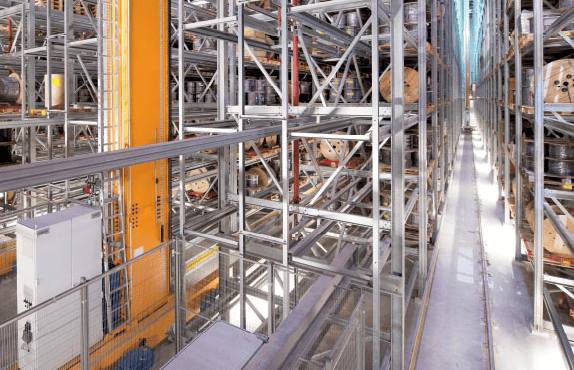

Physical space constraints are pushing companies to optimize existing facilities. Cal Bowers, Director at Kardex Remstar, states that vertical storage technology can save up to 85% of floor space. The development of e-commerce has changed order structures, increased SKU counts, and made inventory management more complex. Surveys show that only 23% of companies have fully integrated systems, with the majority still relying on manual operations.

Sustainability requirements and ergonomic considerations are further driving the adoption of automated warehousing. Ferrell believes these equipment units reduce unnecessary movement, lower energy consumption, and improve overall efficiency. Bowers emphasizes that automated warehousing solutions present components at appropriate heights and are equipped with safety features, having become part of business decision-making.

Faced with market volatility, flexibility has become a key requirement. Ed Romaine, Vice President of Integrated Systems Design, states: "Design and price flexibility are crucial." Modular systems allow companies to expand capabilities as their business grows, reducing upfront investment. Automated warehousing units are being integrated with software, robotics, and more to form complete solutions.

Next month, IMPACT Robotics will launch an automated piece-picking storage system suitable for high-SKU environments, capable of handling individual items without the need for totes. Chris Capshaw, Advanced Technology Manager, claims this system enables dense storage and reduces order cycle times. Future trends indicate that artificial intelligence and machine learning will enhance system intelligence, supporting more autonomous warehousing operations.

Experts advise viewing automated warehousing as a strategic decision involving processes, personnel, and technology, rather than a simple equipment purchase. Bowers concludes: "Treating it as part of an integrated warehouse strategy allows for better preparedness for future development needs." Automated warehousing systems are helping the logistics industry improve efficiency and tackle diverse challenges through technological innovation.