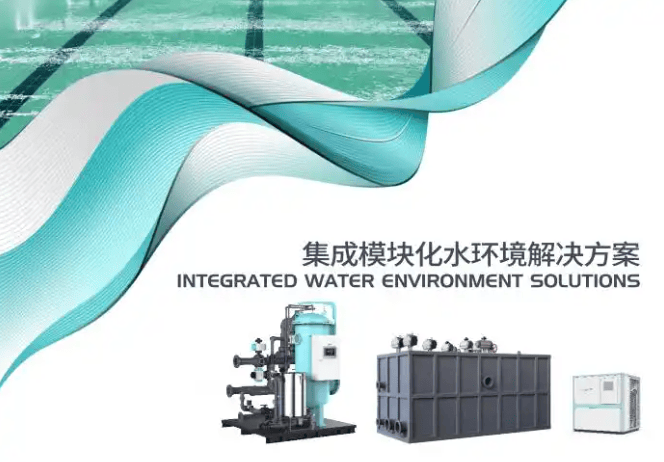

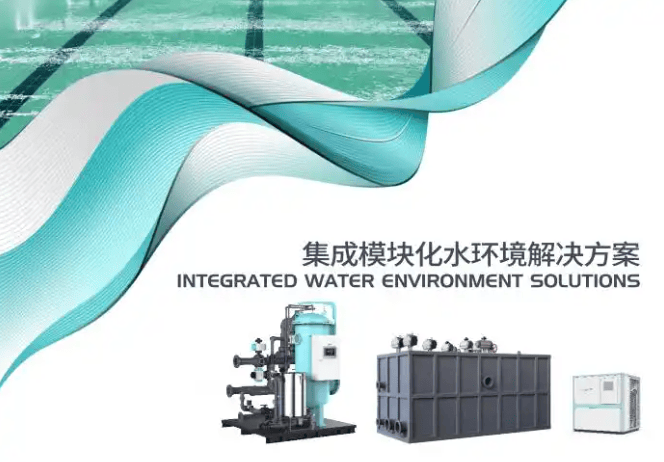

In the swimming pool and water environment engineering industry, a clear trend is emerging: project scales continue to expand, functional requirements keep increasing, yet construction timelines, operational costs, and management complexity are simultaneously expected to decrease. Against this backdrop, the traditional assembled water treatment model centered around individual equipment is gradually revealing systemic bottlenecks. Inconsistent equipment interfaces lead to prolonged debugging periods; operation and maintenance rely heavily on manual labor, resulting in high energy consumption and operational costs. What is truly being consumed is the project's delivery certainty and long-term profitability potential.

It is precisely under this trend that China's LASWIM integrated modular water environment solution is gaining widespread attention from contractors, design institutions, and project owners. As an equipment supplier with over thirty years of deep experience in the water environment field, LASWIM has not remained focused on single equipment upgrades. Instead, from a systems engineering perspective, it attempts to reconstruct the overall logic of swimming pool water treatment.

It is reported that the "integrated modularity" proposed by LASWIM is not merely simple equipment integration, but a system-level solution centered on standardized modules and supported by intelligent control. By completing equipment integration, pre-assembly, and debugging at the factory stage, a large amount of work originally done on-site is shifted forward, thereby significantly reducing on-site construction difficulty and delivery risks.

In terms of integrated system composition, taking the LASWIM Combined Intelligent Water Treatment System as an example, it highly integrates circulation, filtration, disinfection, water quality monitoring, and control modules, achieving centralized management through an intelligent control platform. For engineering contractors, this "turnkey delivery" model effectively compresses construction timelines and reduces uncertainties arising from multi-disciplinary coordination. For operators, it translates to less manpower input, more stable operation, and a more intuitive data management approach.

Regarding filtration structure and system safety, the LASWIM Negative Pressure Filter demonstrates clear engineering-oriented thinking. With a more efficient filtration method, greater processing capacity, a more user-friendly integrated structure, and fewer consumables and space requirements, it meets the core needs of pool water circulation and filtration. The application of such equipment in large-scale projects helps simplify pipeline layout, reduce system complexity, and reserve space for future maintenance and expansion.

More notably, the Smart Clean Pre-coat Membrane Fine Filtration System significantly improves pool water clarity through its higher-precision filtration method. It also performs more prominently compared to traditional sand filter systems in terms of footprint, backwash water consumption, and operational stability. For high-standard pools and commercial pools, such systems not only enhance water quality experience but also lead to a more controllable cost structure in the long run.

When swimming pool projects begin to pursue "intelligent operation and maintenance, standardized delivery, and long-term stable operation," integrated modularity is no longer a forward-looking choice but a real necessity for pool engineering. Based on over thirty years of engineering experience, LASWIM's practice of promoting equipment system integration makes complex water treatment simpler and more controllable.