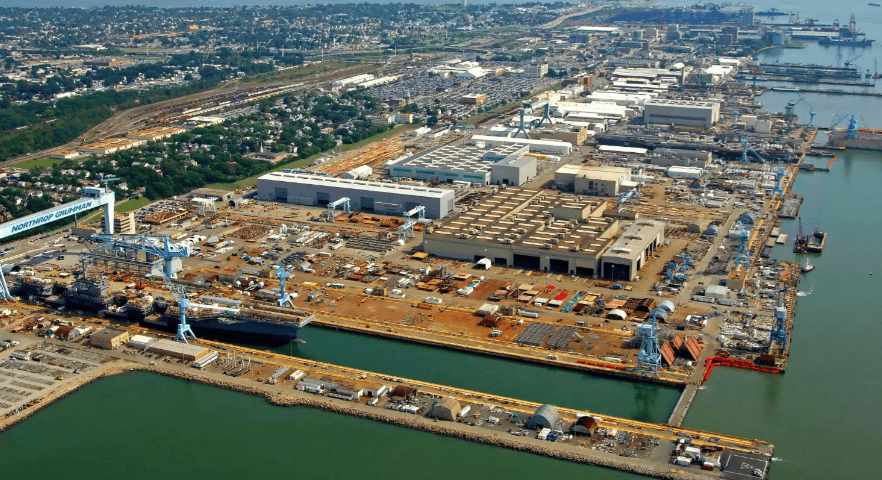

Wedoany.com Report on Feb 13th, As the shipbuilding industry increasingly adopts automation technology, Seaspan Shipyard recently signed a $1.5 million contract with Alberta-based Confined Space Robotics (CSR) to focus on the development and deployment of semi-autonomous robotic systems for blasting and coating operations. This initiative aims to enhance operational efficiency and reduce safety risks.

Surface preparation and coating are critical in new construction, maintenance, and refurbishment projects, especially in confined spaces like submarines, where hazardous materials and high-risk environments pose challenges to worker safety. According to the agreement, CSR will develop collaborative robots equipped with tools such as needle scalers, laser ablation systems, grinders, blasters, and spray equipment. These robots will be mounted on mobile platforms and can be guided by customized path-planning software to optimize workflow.

In shipyard dock areas, blasting and coating tasks are often highly repetitive and physically demanding. By deploying semi-autonomous robotic systems, Seaspan plans to reduce workers' exposure to toxic fumes and particulate matter while alleviating long-term ergonomic stress. The company also expects to improve the consistency and quality of coating thickness and coverage through precise control of material application.

Furthermore, this investment supports environmental sustainability goals. Advanced path-planning software helps optimize material usage, reducing overspray and waste, thereby lessening the environmental impact of coating operations.

This application of robotics is part of Seaspan's efforts under Canada's National Shipbuilding Strategy, aimed at strengthening the domestic supply chain and fostering technological innovation.