Starlab Space LLC and Auxilium Biotechnologies recently announced a partnership to jointly conduct 3D bioprinting and bio-manufacturing projects in an orbital environment. This collaboration marks a new advancement in the field of space biotechnology, with both parties leveraging the microgravity environment to propel scientific exploration.

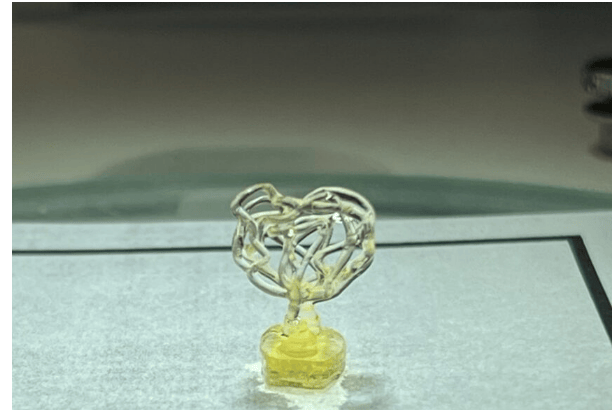

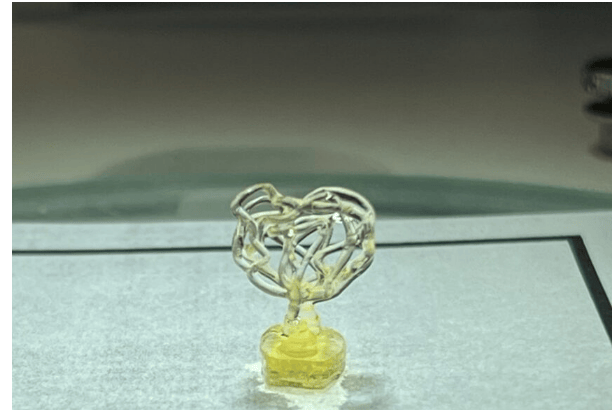

Auxilium will deploy its AMP-1 3D bioprinter on the Starlab space station, providing orbital bioprinting capabilities to support research and production in regenerative medicine, implantable medical devices, and tissue engineering. The 3D bioprinter has previously demonstrated its ability to produce complex structures like implantable medical devices and perfusable vasculature on the International Space Station. Through this collaboration, Auxilium aims to accelerate the translation of experimental results into manufacturable products, positioning AMP-1 as a production platform for space-based life science technologies.

This 3D bioprinter partnership is part of Starlab's broader effort to expand its orbital life science research network. The microgravity environment can promote protein crystallization to optimize drug development, enable 3D cell culture and disease modeling under conditions more akin to the human body, and advance stem cell research for diseases such as Parkinson's.

Starlab adopts a market-oriented model aimed at reducing research costs and risks. Its space station is designed for a single launch, requiring no in-orbit assembly, which allows for quicker certification and operation, reducing customer delays and improving efficiency. Through existing partnerships, customers can conduct research on the International Space Station and seamlessly transition their orbital bioprinting projects to Starlab for future development.