The Fraunhofer Institute for Material and Beam Technology (IWS) and the Max Planck Institute for Plasma Physics (IPP) in Germany have jointly launched the "TritiumStopp" project to develop high-performance barrier coatings for nuclear fusion reactors, aimed at preventing tritium fuel leakage.

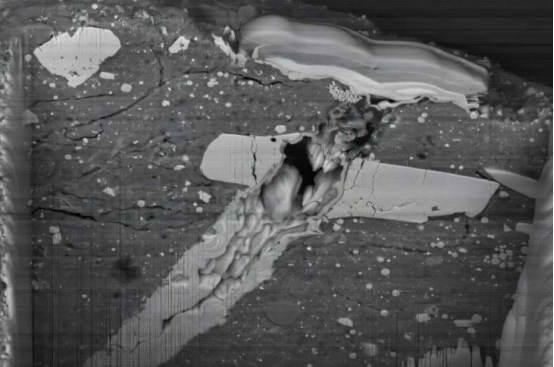

Tritium is a critical fuel for nuclear fusion reactions, but its extremely small atomic size makes it prone to penetrating metal structures (a phenomenon known as "permeation"), leading to tritium escape from reactor walls or pipelines. This results in the loss of an irreplaceable strategic resource. To address this issue, the research team is focused on developing thin coatings capable of withstanding extreme conditions to block tritium migration within materials.

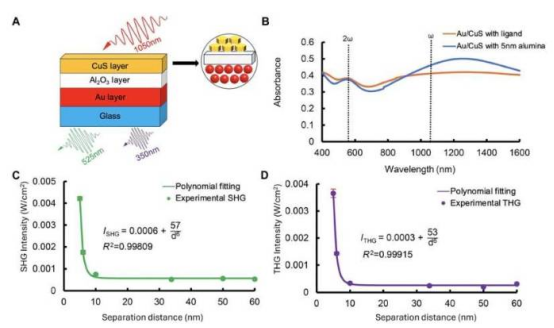

The coating technology employed by Fraunhofer IWS is based on physical vapor deposition (PVD) processes, previously validated in high-performance industrial applications such as heavy-duty tool wear protection. This production-ready approach can be directly applied to reactor base components.

The project team is investigating the anti-permeation performance of various coating types, including metal nitrides, oxides, and diamond-like carbon (DLC). Dr. Volker Weihnacht from Fraunhofer IWS explained: "We are testing coating performance under simulated reactor environments, including mechanical stress, thermal cycling, and high-energy particle irradiation." The research aims to verify the immediate protective effects and long-term stability of the coatings.

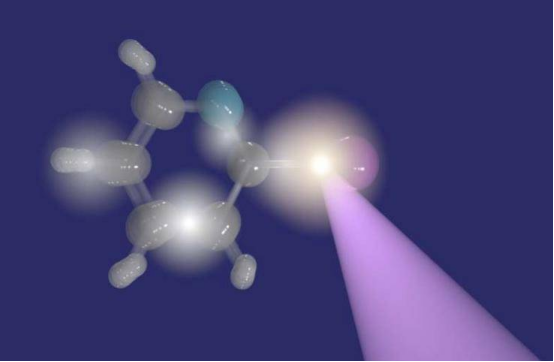

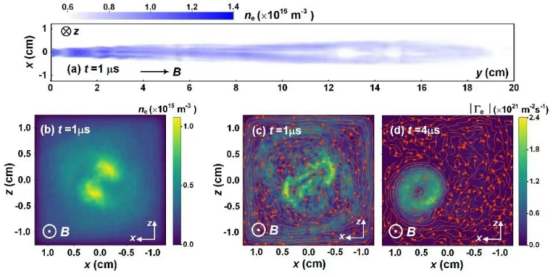

Dr. Armin Manhard from the Max Planck Institute for Plasma Physics added that the team draws on long-standing expertise, using high-resolution ion beam diagnostics to track hydrogen isotope diffusion in fusion materials across multiple permeation test rigs. He emphasized: "We integrate various diagnostic methods to reveal material behavior and identify the influence of process parameters."

Beyond foundational research, the project team is simultaneously exploring pathways for practical implementation. Dr. Weihnacht noted: "From the project's outset, we have considered scaling up through large-area coatings or integrated protection systems to broaden application scope." This technology holds promise for future scalable protective systems in fusion reactors.

Nuclear fusion reactions involving hydrogen isotopes are viewed as a potential solution for clean energy, and the stable supply and safe storage of tritium are prerequisites for commercializing the technology. This research aims to provide reliable material protection solutions for future fusion power plants.