The Australian Research Council Centre of Excellence for Transformative Meta-Optical Systems (TMOS) recently published significant research results in Laser & Photonics Reviews, successfully developing a new thermally tunable infrared filter based on silicon nanotechnology. This breakthrough technology promises to fundamentally reshape the market for existing infrared spectroscopy equipment, transforming high-cost desktop spectrometers—priced from $10,000 to $100,000—into portable, low-cost detection tools.

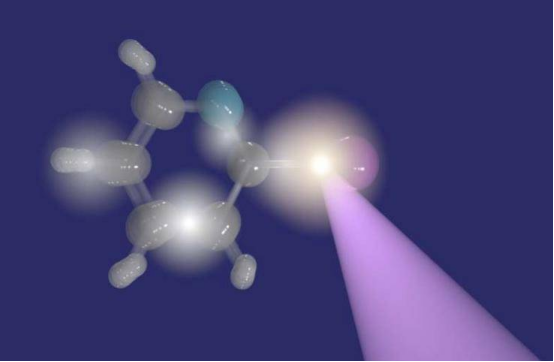

Led by TMOS Deputy Director Professor Kenneth Crozier, the team innovatively leveraged the temperature-dependent refractive index of silicon to design a nanoscale bandpass filter with tunable functionality. "While traditional infrared spectroscopy technology is mature, equipment is bulky and expensive," said Professor Crozier. "Our solution dramatically reduces costs while achieving miniaturization and portability."

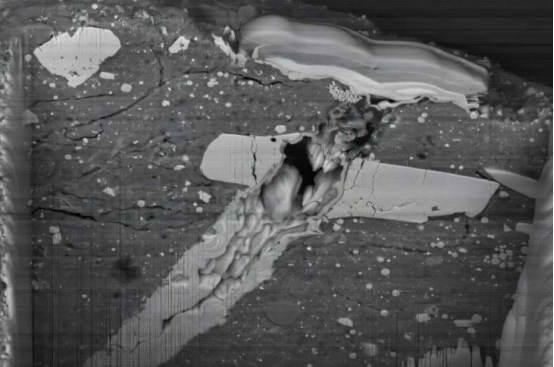

The core of this technology lies in using a 1.5-micrometer-thick silicon layer as the base material, with precise nanofabrication etching specific metasurface patterns on the surface. As the primary developer, PhD student Ben Russell detailed the process: "We tested two different nanostructure designs—parallel grooves and cross grooves—and ultimately selected the cross pattern, which is insensitive to light polarization." Experimental data showed that the filter achieves linear wavelength tuning of 80 nanometers across operating temperatures from 25°C to 420°C, with the range expandable to 140 nanometers under extreme conditions.

The research team verified the system's reliability through multiple real-world tests, including successfully distinguishing spectral characteristics of polyimide tape and zinc selenide windows, as well as accurately identifying different plastic materials like LDPE and PET. "The filter's most notable advantage is its stability and reversibility," emphasized Dr. Russell. "It maintains performance even after multiple temperature cycles."

The technology's potential applications are vast. Professor Crozier noted: "In agricultural product testing, it enables on-site rapid detection of products like milk and olive oil; in environmental monitoring, it supports pollutant detection and recycling material classification; in industrial processes, it aids real-time quality control and safety monitoring." The team particularly highlighted that, fully based on mature silicon processes, the mass production cost per filter could drop below $1, greatly promoting the widespread adoption of infrared spectroscopy technology.