An international team of scientists has recently created a porous rock analog for oil recovery studies, opening a new path for reliable and cost-effective laboratory testing in the fields of oil, gas, and rock physics. The research has been published in the journal Engineering Results.

In oil recovery research, developing synthetic analogs of porous rocks—known as cores—has been a hot topic. Natural cores are expensive to extract from the ground and offer low experimental reproducibility. In contrast, synthetic cores are low-cost, structurally homogeneous and identical, with experiments based on them providing high stability. The preparation of typical rock samples is crucial for research in the oil and gas industry, geotechnical engineering, and other fields, primarily for quality control in laboratory measurements.

"The main goal of our work is to develop technologies for enhanced oil recovery. Modeling is an ideal way to achieve this, but models need experimental validation. Our experience with real core samples shows that they can have various influences, such as pore clogging by flowing clay, inability to reproduce natural boundary conditions, and other experimental errors. Simple artificial samples allow us to study different processes separately," said Kirill Gerke, Scientific Director of the LFI Center for Computational Physics. "To do this, we need to solve the problem of creating artificial samples with known properties. Unfortunately, printing methods cannot yet solve all issues, but printing technology is developing rapidly. We hope that in the near future, we will not only create models but also print samples with any physical properties."

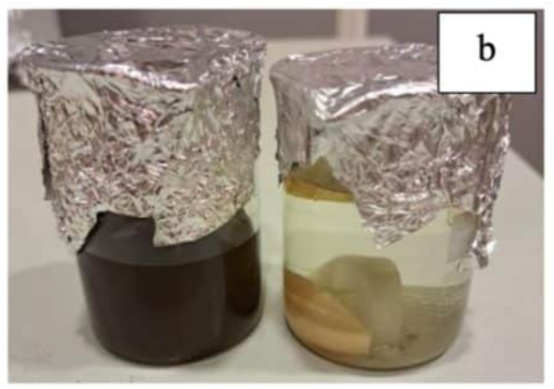

In this study, physicists used stereolithography to print synthetic cores from polymer resin. The resulting products were then tested for wettability, permeability, and reproducibility of natural rock displacement efficiency under simulated subsurface conditions

The tests showed that the 3D-printed cores exhibited neutral wettability to water and strong wettability to condensate oil. Wettability characterizes a surface's ability to attract or repel liquids; neutral wettability indicates weak hydrophobicity, while complete coverage by condensate oil (a hydrocarbon liquid) indicates strong wettability.

Another key property of cores is permeability—the ability of rock to allow liquids and gases to pass through. During the study, defects affecting liquid flow appeared in the samples. After treatment, permeability stabilized at 40 darcies, which remains high for real rocks. For laboratory studies, the stability of sample properties is a critical characteristic.

In tertiary oil recovery, nitrogen or carbon dioxide is used to displace oil from reservoirs. The scientists conducted an experiment displacing condensate oil with nitrogen, extracting 88% of the liquid from the synthetic core. This data confirms that the core simulates displacement effects close to those of natural cores.

Further studies showed that the product has mechanical and thermal stability under conditions identical to underground reservoirs. This proves that the developed cores are effective analogs of natural cores, and their use could significantly reduce the costs of selecting enhanced recovery methods.

3D-printed synthetic cores are a promising alternative to natural samples in oil recovery research. They offer reproducibility and customizable properties, and scientists hope to achieve high precision in the future. 3D printing technology can be scaled up, enabling cost-effective testing of oil recovery methods.

The scientists involved in this work are from the Center for Computational Physics at the Landau Phystech School of Physics and Technology (Moscow Institute of Physics and Technology), Persian Gulf University (Iran), and the Schmidt Institute of Physics of the Earth (Russian Academy of Sciences).