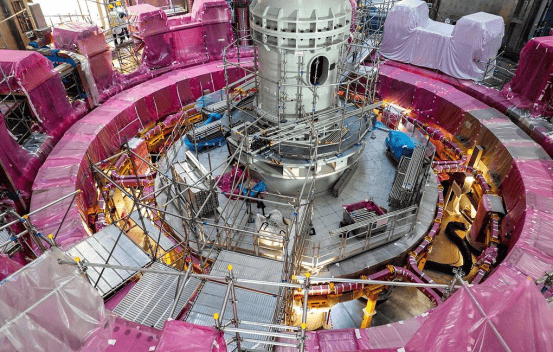

As the preliminary modeling nears completion and the preliminary design is finalized, engineers and scientists on the International Thermonuclear Experimental Reactor (ITER) project are adapting proven technologies to meet the scale and complexity of fusion experiments.

Tom Keenan, ITER’s Wall Conditioning Engineer, said: "We are using a mature technology, but it has never been applied at this scale or in a tritium environment, so it’s a fascinating area."

The work involves a new wall-conditioning system known as boriding. In 2023, ITER decided to switch the plasma-facing armor tiles from beryllium to tungsten, making this system essential. The system is designed to deposit a 10–100-nanometer-thick layer of boron on all plasma-facing surfaces to buffer the increased impurities that come with the change. This boron layer will trap or "getter" oxygen, which would otherwise increase radiative losses and disrupt the plasma, especially during the discharge start-up phase.

To achieve this, the team will use diborane (a compound of hydrogen and boron). Diborane at 5% concentration, carried by helium gas, will be injected into the tokamak. Once inside, the diborane decomposes and, with the aid of glow-discharge assistance, deposits onto the plasma-facing walls, generating a cold plasma that chemically binds the boron to the material surface.

The preliminary design of the gas injection system shows more than one kilometer of piping inside the tokamak building, an additional 400 meters of piping inside the vessels, and 21 gas injection points. Fueling Process Integration Engineer Gábor Kiss said these modifications are not expected to affect the plant's installation sequence.

Although ITER's design already includes glow-discharge cleaning for maintenance, adapting it for frequent boriding presents two major challenges. The first is whether ITER's high-energy anode design can withstand frequent cycling — tests to be conducted soon on China's EAST tokamak will provide the answer. The second is determining the optimal anode positions to achieve uniform boron coverage. Solving this required international collaboration. ITER plasma-wall interaction expert Tom Waters noted that it was the result of joint efforts with experts from the International Tokamak Physics Activity. In its press release, ITER emphasized that, through modeling and collaborative testing with the ASDEX Upgrade (Germany) and WEST (France) tokamaks, the team decided to add four anodes inside the vacuum vessel to achieve the most effective boron distribution.

As the design progresses, operational issues are also being addressed, such as the frequency of boriding treatments. Recent studies indicate that a single application remains effective for 2.5 to 12.5 weeks, so the maximum planned interval is every two weeks.

Because diborane is both toxic and explosive, special safety measures are required. The compound will be stored in a dedicated safe "gas bunker" built outside the diagnostic building. Any undecomposed diborane extracted from the tokamak must be neutralized. Two neutralization methods are currently under evaluation: heating the gas to 700 °C for thermal decomposition or using proprietary chemical scrubbers.