Deepwater regions have become the primary arena for major oil and gas discoveries, accounting for 44% of global marine hydrocarbon reserves. Over the past decade, deepwater has served as the core succession area for production growth, representing 67% of the number and 68% of the reserves among the world's 101 newly discovered giant fields.

However, deepwater oil and gas development faces challenges of high pressure, low temperature, and complex fluid compositions, leading to solid-phase hydrate blockages in long-distance multiphase transport pipelines from reservoir to wellbore, subsea facilities to downstream processing. Such blockages can cause production shutdowns at best and leaks or explosions at worst. Therefore, understanding the intrinsic mechanisms of hydrate nucleation-growth-aggregation-blockage and establishing an effective intelligent prevention and control system is a major scientific and engineering challenge.

Addressing these issues, the team led by Professor Song Yongchen and Associate Professor Zhang Lunxiang at Dalian University of Technology has focused on deepwater conditions in the South China Sea, developing key technologies and equipment for hydrate formation and blockage in multiphase transport systems and achieving significant progress. Their work has been applied to flow assurance at multiple deepwater oil and gas platforms in the South China Sea.

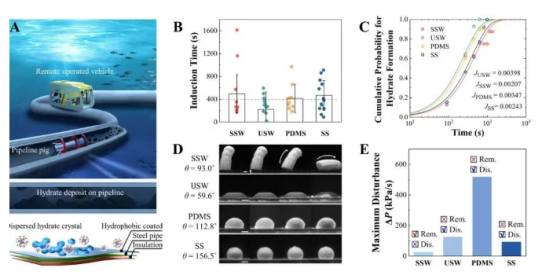

Current deepwater operations primarily rely on injecting chemical inhibitors to suppress hydrate formation, but complete prevention is often impossible in long-distance pipelines. Compared to post-formation removal, preventing hydrate deposition on pipe walls from the source is far more critical, with the core strategy being to minimize contact probability between free water and the pipe wall.

Based on this prevention philosophy, the Dalian University of Technology Hydrate Flow Assurance Team adopted hydrophobic surfaces as a passive control method and successfully developed a novel functional material with anti-hydrate deposition properties. They innovatively proposed the concept of "moderate hydrophobicity" — achieving easy hydrate removal by tuning surface chemistry rather than physical structure while maintaining relative surface smoothness.

The designed silanized hydrophobic surface creates a unique interfacial effect that causes hydrate crystals to spontaneously lift during growth and form loose, porous structures. This research provides a new solution to hydrate blockage in deepwater oil and gas production. The team is currently optimizing material performance parameters to deliver more robust technical support for industrial field applications.

Professor Liu Yu and Dr. Lang Chen from the team explained to DeepTech: "This self-lifting crystal has minimal contact area with the surface, making it very easy to remove. This phenomenon offers a new approach to addressing hydrate prevention challenges in marine hydrocarbon transport."

The related paper, titled "Spontaneous Lifting and Self-Cleaning of Gas Hydrate Crystals," was recently published in ACS Nano.

To achieve precise hydrate blockage control and improve the efficiency and cost-effectiveness of the new functional material, Professor Song Yongchen's team collaborated with the flow assurance team led by Chief Engineer Yao Haiyuan from CNOOC Research Institute Co., Ltd. They jointly developed a series of hydrate formation and blockage monitoring, detection equipment, and early-warning software systems. The teams conducted multiple field visits to deepwater assets in the South China Sea, including the "HYSY 119 FPSO" and "Deep Sea No.1," to investigate hydrate formation conditions and high-risk blockage locations in complex transport pipelines, ultimately forming effective integrated prevention and control strategies.

Associate Professor Zhang Lunxiang noted that in practical applications, this surface modification technology primarily targets critical blockage-prone sections (such as dead legs and bends) for optimized design. Considering the economic constraints of treating entire pipelines, the team proposed an engineering strategy of "precise modification at key locations."

Chief Engineer Yao Haiyuan, Engineer Li Yan, and others pointed out that industrial pipeline blockages involve multiphase flow and multicomponent systems. In addition to hydrates, deposits such as paraffin and asphaltenes are common, often accompanied by sand erosion and corrosive gases like CO₂.

Therefore, future research must further validate the long-term stability of the material under complex conditions, including wear resistance, corrosion resistance, and other engineering performance metrics. The team has established a systematic research direction centered on "flow assurance," covering three main levels:

Fundamental theory: Studying hydrate formation and blockage mechanisms in multiphase flow systems and building new theoretical frameworks to provide a scientific basis for subsequent blockage solutions

Technology development: Collaborating with CNOOC and others to develop hydrate monitoring and detection equipment along with supporting software for real-time blockage location identification

Material innovation: Developing new anti-hydrate materials for high-risk sections and complex conditions, while exploring inhibitor compounding and blockage removal techniques to enhance overall prevention efficiency

This "theory–technology–material" research framework provides a systematic solution for flow assurance in deepwater oil and gas production. The team hopes it will play a critical role in real-world applications in the future.