Michigan State University has achieved a major advance in lithium-ion battery technology, with results published in Advanced Materials. The technique is currently being patented through the university's innovation center. This discovery brings good news to consumers concerned about lithium-ion battery risks, improving safety, extending lifespan, and enhancing environmental sustainability.

Assistant Professor Chengcheng Fang from the College of Engineering and Associate Professor Mojgan Nejad from the College of Agriculture and Natural Resources collaborated to engineer lignin—a natural component of wood—into a thin-film separator that prevents short circuits inside lithium-ion batteries. Professor Fang stated: "We want to make better batteries that are also safe, efficient, and sustainable."

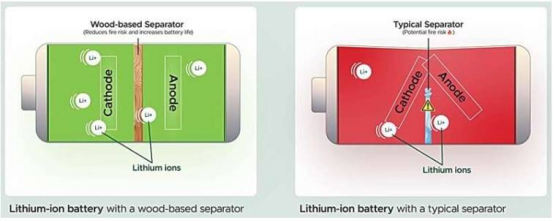

In lithium-ion batteries, positively charged cathodes and negatively charged anodes facilitate current flow. Commercial separators are typically made of polyethylene and polypropylene plastics, which shrink near 100°C, losing their protective function and potentially allowing cathode-anode contact, leading to short circuits, fires, or explosions. The newly developed lignin-based separator remains stable and dimensionally unchanged even at temperatures up to 300°C.

After testing lignin films of different thicknesses, the team found that a 25-micron film (thinner than one-quarter of a human hair) best maintains internal battery stability and prevents anode-cathode connection.

Moreover, the lignin film brings additional benefits. Enhanced internal stability significantly extends cycle life—the number of charge-discharge cycles a battery can undergo. Professor Fang noted that the team was surprised to find the lignin film increased battery cycle life by 60%.

Environmentally, the team uses a low-cost dry processing method to manufacture lignin separators, enabling on-demand mass production while avoiding harmful solvents commonly used in traditional separator manufacturing. This achieves 100% raw material conversion with zero waste or pollution. Fang explained that lignin, particularly lignosulfonate, is naturally abundant and requires no further treatment to function effectively in batteries.

This research demonstrates a new design approach to improve the safety and manufacturability of battery materials, poised to drive the lithium-ion battery industry toward safer, more durable, and more environmentally friendly solutions.