Oil sludge, a hazardous waste from oil extraction containing hydrocarbons, heavy metals, and chemicals (1 ton generated per 500 tons of oil produced), poses a serious threat to ecosystems. Scientists from Perm propose using pyrolysis to process oil sludge and obtain carbon-containing products. The study was published in Glass and Ceramics and conducted under the Priority 2030 Strategic Academic Leadership Program.

Ceramics are made from clay mixtures with additives that improve durability and firing quality. Combustible additives like coal, peat, or sawdust increase porosity, partially replace clay, and reduce production costs, while their oxidation during firing saves fuel. However, additives and heat treatment must be carefully selected; incomplete oxidation can cause material swelling, black coring, and reduced performance.

Adding 15–20% carbon-containing product obtained from oil sludge pyrolysis to ceramics makes them lightweight, porous, and durable while lowering energy costs. This material can be used to manufacture construction products or water purification filters. Scientists from Perm National Research Polytechnic University have developed a technology to produce high-quality porous ceramics from this material, offering a potential solution for recycling waste from the oil and refining industries.

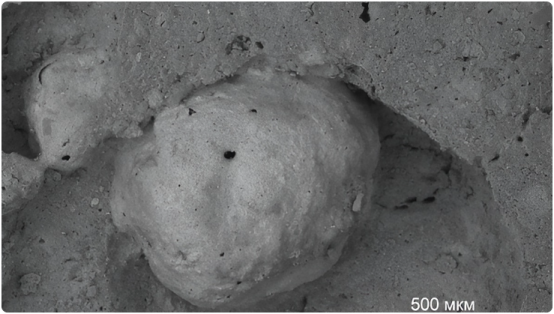

The experiments used oil sludge from a Russian refinery, which is typically dewatered and then pyrolyzed, yielding black granular carbon-containing products that remain unused. Experts found that 1kg of this product saves 1.28MJ of energy during ceramic firing, replaces 762g of clay raw material, and reduces fuel and clay costs.

To determine the optimal production method, scientists produced ceramic samples from clay without additives and with 10–30% carbon-containing material added, then fired them at 900–1,200°C for two hours. Results showed that adding oil sludge pyrolysis residue lowers the firing temperature from 1,150°C to 1,080°C, reducing energy consumption and making the process more economical. Adding 15–20% of the product proved optimal, increasing ceramic porosity and promoting a unique structure with abundant glass phase, enhancing material strength.

Associate Professor Elena Kalinina from the Department of Environmental Protection at Perm State University noted that this approach makes it possible to produce commercial products from oil sludge pyrolysis residue. The resulting ceramics have high porosity and strength, suitable as expanded clay or biomass carriers in biological water treatment systems. The university's research demonstrates the potential of oil-containing waste pyrolysis residue in ceramic production. Industrial application would significantly reduce hazardous waste while yielding practical, high-quality products.