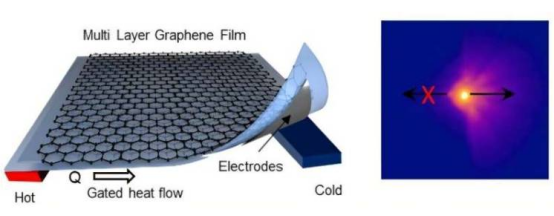

A research team from the National Graphene Institute at the University of Manchester has recently developed a novel electrically controlled heat flow device, with the potential to revolutionize thermal management systems for aerospace and electronic equipment. The research findings have been published in the journal Science Advances.

The research team utilized highly conductive graphite films to design a thermal switch device. When voltage is applied, ions intercalate between the graphite layers, disrupting phonon movement and reducing thermal conductivity by up to 13 times. Upon removal of the voltage, the ions are expelled, and the graphite film restores its original thermal conductivity. This reversible regulation mechanism enables heat control functionality similar to that of an electronic transistor.

"This breakthrough represents a significant advancement in thermal management technology. For the first time, we have achieved precise and reversible control over heat conduction," said project leader Professor Koskun Kocabas. Team member and Technical Director of SmartIR, Dr. Pietro Steiner, added: "The device's reliability in extreme environments such as space gives it special application value."

The technology not only enables on/off control of heat conduction but can also direct heat flow through electrode pattern design. Kocabas noted: "This solid-state thermal switch can replace bulky heat dissipation systems on spacecraft, providing more flexible thermal management solutions." Compared to traditional thermal control systems relying on mechanical valves, this design with no moving parts is more reliable and lighter in weight.

Currently, the research team is testing the device's response speed under high thermal loads and plans to integrate it into electronic device prototypes. In the future, by optimizing ion migration speed and exploring new intercalation materials, performance is expected to be further improved.