A waste incineration plant in Finland has adopted glass fiber reinforced polymer (GFRP) pipes to store excess heat 1.2 miles underground, reshaping energy storage and waste heat recovery models.

The Lounavoima waste-to-energy plant in Salo collaborated with global composites manufacturer Exel Composites and geothermal technology company QHeat on this R&D project. The new thermal energy storage system was completed by late July, aiming to capture and store up to 14 gigawatt-hours (GWh) of excess heat in the granite bedrock beneath the facility. Exel Composites states that the stored energy will be released during cold months to reduce dependence on fossil fuels.

QHeat CEO Erika Salmenvaara explained: “With half of the world’s energy used for heating, we see significant environmental benefits in electrifying heating.”

Before installing the storage system, the Lounavoima plant processed up to 120,000 tons of municipal waste annually, releasing excess heat into the air during summer. In winter, when temperatures in Finland drop to -4°F (-20°C), the plant relied on oil burners for supplemental heat. With the new setup, the facility can use stored energy to heat approximately 700 standalone homes each year, reducing emissions and improving efficiency.

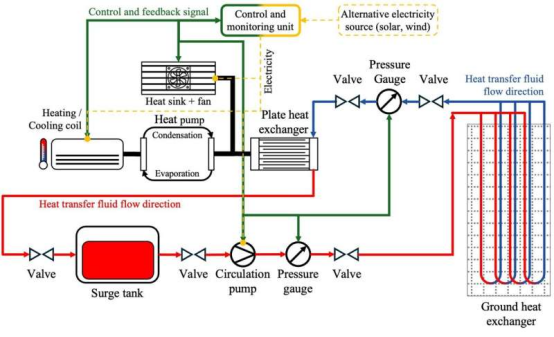

Salmenvaara noted that 60% of heating in the EU still relies on fossil fuels, with the remaining 40% mainly from natural gas and waste incineration. She acknowledged that electric heating is not perfect and puts pressure on aging power grids, but innovative engineering solutions can address this. Heat pumps, she mentioned, are 600% more energy-efficient than direct electric heating.

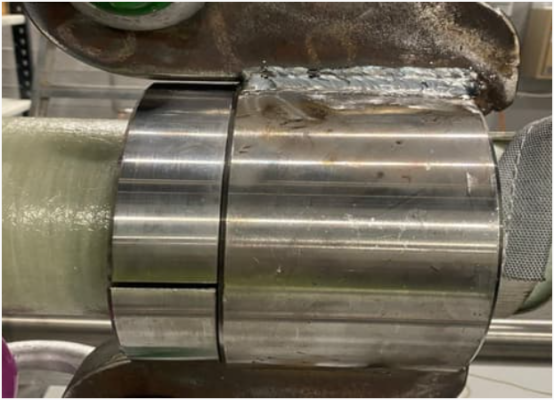

The system uses specially designed GFRP pipes capable of withstanding the extreme conditions of underground heat storage. These pipes are lightweight, corrosion-resistant, and highly thermally efficient—a result of close collaboration between Exel Composites and QHeat. The teams went through multiple iterations to optimize size, connection methods, and the balance between insulation and mechanical strength.

Exel Composites Technical Sales Manager Tiina Uotila revealed: “Combining insulation performance with good mechanical properties is the most critical criterion for these pipes. We worked with QHeat to understand how to make the pipes easier to assemble and install, while ensuring a clear and sustainable end-of-life solution.”

These pipes are specifically engineered to handle the pressure and temperature of underground storage, with improved insulation for higher energy efficiency. According to Uotila, the pipes’ sustainability extends beyond heat storage—their design allows reuse after service life. Once they reach the end of use, they are not landfilled but processed into cement, where the composites replace fossil fuels and virgin raw materials.