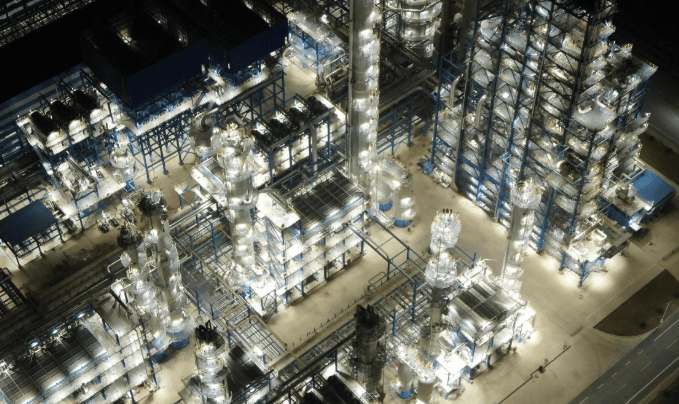

Wedoany.com Report-Nov. 7, Mitsubishi Heavy Industries, Ltd. (MHI), a global leader in engineering and technology, has entered into a strategic alliance with ICM, Inc., a U.S.-based process technology company specializing in bioethanol production. The collaboration aims to accelerate innovation in ethanol dehydration by combining MHI’s Mitsubishi Membrane Dehydration System (MMDS™) with ICM’s bioethanol process design, improving efficiency, reducing energy consumption, and supporting efforts to lower carbon intensity in bioethanol manufacturing.

MHI recently achieved ethanol purity exceeding 99.5 vol.% using MMDS™ at a pilot plant located at the Nagasaki Carbon Neutral Park within its Nagasaki District Research & Innovation Center. The pilot tests demonstrated a significant reduction in energy usage compared with conventional dehydration technologies. Building on these results, both companies will conduct additional validation programs as they prepare for large-scale development and commercial application.

Two major verification stages are planned: a fouling test and a demonstration test. The fouling test will evaluate membrane durability and its resistance to impurities in ethanol streams, ensuring long-term stable operation. The demonstration test will assess the system’s performance in an industrial environment, confirming efficiency, reliability, and seamless integration with ICM’s existing process design.

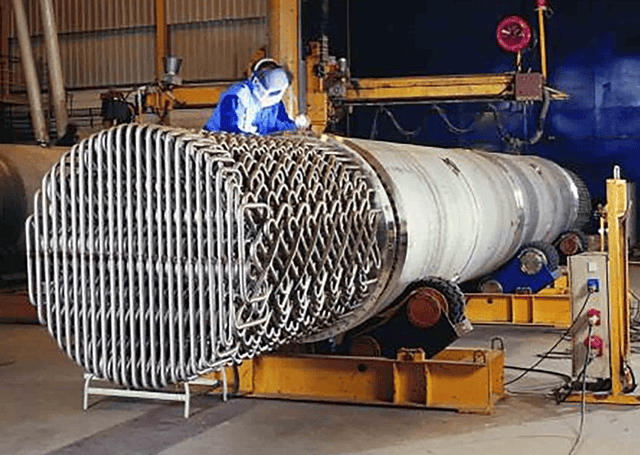

Ethanol dehydration is one of the most energy-intensive steps in bioethanol production. MHI’s MMDS™ replaces the traditional Pressure Swing Adsorption (PSA) method with a molecular sieve separation process, which allows dehydration in the liquid phase. This approach enables compact system design, lower energy consumption, reduced operational costs, and simplified installation, making it suitable for large-scale industrial adoption.

“Through this collaboration with MHI, we’re exploring new approaches to ethanol dehydration that can further improve efficiency and reliability in ethanol production,” said Shaun Hubler, Director of Technology Commercialization at ICM, Inc. “The pilot results are very promising, and we look forward to building on them as we move toward full commercial deployment.”

“This partnership represents an important step toward realizing MHI’s vision for carbon-neutral industrial solutions,” said Fumitaka Miyashige, Business Manager of the MMDS™ project at MHI. “Working with ICM allows us to bring this advanced separation technology to the global renewable fuels market.”

Further testing is expected to begin in the second quarter of 2026, marking a key milestone toward the first commercial installation of the technology. Both companies view the alliance as a long-term cooperation aimed at advancing energy efficiency, sustainability, and competitiveness in the global bioethanol sector.

Founded in 1995 and headquartered in Colwich, Kansas, ICM operates globally with more than 110 facilities producing approximately 8.8 billion gallons of ethanol annually. Mitsubishi Heavy Industries, with operations across energy, infrastructure, industrial machinery, aerospace, and defense, continues to develop integrated technologies that contribute to a carbon-neutral and sustainable future.