Wedoany.com Report-Nov. 8, Blue Circle Olefins has secured funding for the next stage of ProjectNL, aimed at developing a commercial methanol-to-olefins (MTO) production facility in the Netherlands. The investment, provided by a consortium of private investors along with a Kansen voor West subsidy, allows the company to begin conceptual engineering and the permitting process for the project.

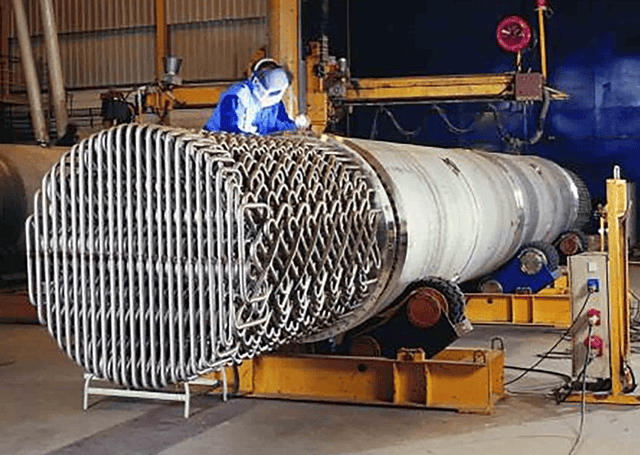

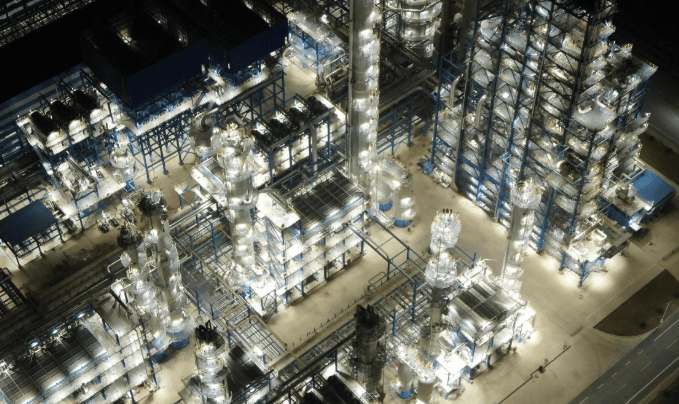

The proposed 200,000-ton plant will be highly electrified and convert sustainable methanol into 100% circular ethylene and propylene, which serve as the foundational building blocks for approximately 60% of all chemical products manufactured in Europe. Once operational by 2030, the facility is expected to reduce life cycle greenhouse gas emissions of plastics—including polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC)—by more than 80% compared to conventional fossil-based production methods.

Blue Circle Olefins has chosen Rotterdam as the preferred location for the project, leveraging its status as Europe’s largest methanol hub. Ralph Koekkoek, CEO of Blue Circle Olefins, stated: “Securing this funding represents an important step in the development of ProjectNL. It provides the means to begin the conceptual engineering and permitting phase, a crucial stage on the path to reaching commercial operation in 2030. As the largest methanol hub in Europe, the Port of Rotterdam offers the ideal location to realise this facility.”

Nico van Dooren, Director of New Business at the Port of Rotterdam, added: “We welcome Blue Circle Olefins in the Port of Rotterdam and are looking forward to facilitating them in the final site selection process. The production of fully circular chemical feedstocks is an excellent fit with our strategy to become a climate neutral and circular Port contributing to resilience, security of supply and strategic autonomy.”

Blue Circle Olefins focuses on scaling up a future-proof chemical industry in Europe by producing and selling circular olefins as drop-in replacements for fossil-based equivalents. The facility will utilize green methanol derived from mixed plastic waste, as well as agricultural and forestry residues, providing a commercially viable pathway to fossil-free plastics and chemicals.

The project is expected to support local supply security, reduce dependence on oil and gas imports into Europe, and advance the transition to a circular economy in the chemical sector. ProjectNL represents a key step in the broader European effort to decarbonize plastics production while maintaining industrial competitiveness and strategic autonomy in critical chemical feedstocks.

With construction and operational planning now underway, Blue Circle Olefins aims to complete ProjectNL by 2030, establishing a benchmark for sustainable, circular chemical production in Europe and demonstrating the commercial viability of large-scale methanol-to-olefins technology.