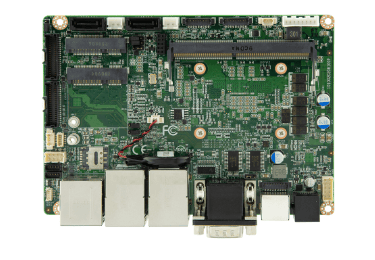

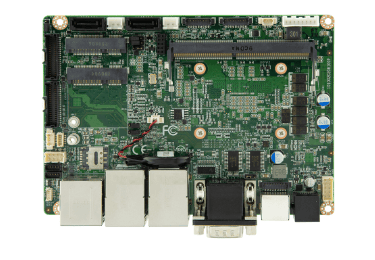

Wedoany.com Report on Feb 3rd, Recently, AI technology has continued to develop in the field of Electronic Design Automation (EDA), achieving practical progress particularly in the layout and routing of Printed Circuit Boards (PCBs). Quilter.ai has successfully designed and manufactured a functional single-board computer (SBC) through its Speedrun project, validating the practical capabilities of AI tools in complex PCB design.

This project was completed by the Quilter.ai team, including founder Sergiy Nesterenko, product manager Ben Jordan, and sales vice president James Krejcarek. They selected the NXP i.MX 8M Mini reference design as the foundation, focusing on core aspects such as automatic component placement, routing, stackup selection, and constraint management. The design incorporates an LPDDR4 memory interface, involving challenges like controlled impedance, length matching, and signal integrity, reflecting the complexity of real-world engineering applications.

Quilter.ai's approach is not to replace human engineer decision-making but to assist in completing time-consuming manual layout tasks. The team followed a professional workflow, starting from existing schematics, bill of materials (BOM), and mechanical constraints, and then utilized AI for subsequent layout optimization. In testing, the generated System-on-Module (SOM) and baseboard were able to boot and run software normally and were compatible with the original hardware.

Compared to traditional manual design, the Quilter tool significantly improved efficiency. The manual quotation for the same design task was approximately 400 hours, whereas with the AI tool, the SOM layout took only a few hours, and the baseboard was completed in about a day. This provides the possibility for rapid iteration in prototype development and small-batch production, especially for time-sensitive project phases.

Quilter.ai supports data exchange with mainstream EDA platforms such as Altium Designer and Cadence Allegro/OrCAD, facilitating integration into existing design workflows. The team stated that the tool is primarily suitable for prototype design and small-batch scenarios, rather than highly optimized designs for mass production. Sergiy Nesterenko pointed out: "If you only need a few prototype boards, getting engineers working hardware early is far more important than optimizing the cost per board."

This practical demonstration shows that AI-driven PCB layout tools are now capable of handling real-world design tasks, offering a new path for efficiency improvement in the field of electronic design.