Wedoany.com Report on Feb 9th, A Japanese research team has successfully prepared tungsten carbide-cobalt alloy with industrial-grade hardness using an additive manufacturing method. This technology employs a hot-wire laser irradiation process, enabling precise material deposition in designated areas, thereby significantly reducing raw material consumption and production costs.

Tungsten carbide-cobalt alloy is widely used in cutting tools, molds, and engineering equipment manufacturing due to its extremely high hardness and wear resistance. Traditional powder metallurgy processes require high-pressure and high-temperature sintering. Although they can achieve the desired properties, they consume large amounts of expensive tungsten and cobalt materials, and face issues such as significant material loss and difficulty in design adjustments when processing complex-shaped components.

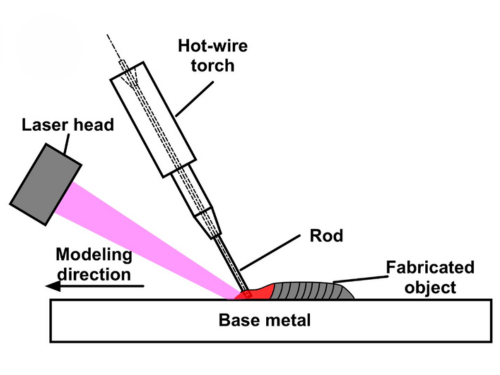

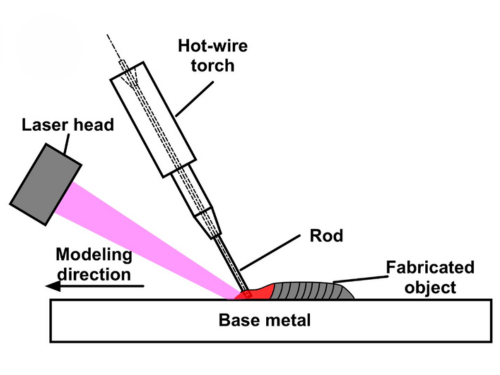

Additive manufacturing technology provides a new approach for precise material placement, but improper heat control during the process may lead to tungsten carbide degradation, affecting the integrity of the final structure. The hot-wire laser irradiation method developed by the research team combines a laser beam with a preheated filler wire, achieving material bonding through softening rather than complete melting. This effectively reduces thermal damage and preserves the material's microstructure.

During the experiments, researchers tested two different deposition strategies: the rod-guided method and the laser-guided method. The former was found to cause decomposition of the top-layer tungsten carbide, while the latter exhibited issues with insufficient hardness uniformity. By introducing a nickel alloy interlayer and precisely controlling the process temperature, the team successfully resolved these technical challenges.

The tungsten carbide-cobalt alloy prepared by the optimized process has a hardness exceeding 1400 HV, meeting industrial application standards, with no significant defects or material decomposition observed. Corresponding author Keita Marumoto stated: "Hard metals are extremely hard materials used for cutting tool edges and similar applications, but they are made from very expensive raw materials like tungsten and cobalt, so reducing material usage is highly desirable. By using additive manufacturing, hard metals can be deposited only where needed, thereby reducing material consumption."

Marumoto further pointed out: "The method of forming metallic materials by softening rather than completely melting is novel. It has the potential to be applied not only to the hard metals focused on in this study but also to other materials." Currently, the research team is working on reducing material cracking and expanding the manufacturing capabilities for complex shapes. Future research directions include cutting tool manufacturing, exploration of alternative material systems, and enhancement of industrial application durability.

The research results were published online in the International Journal of Refractory Metals and Hard Materials in December 2025 and will be included in the print version in April 2026. This laser-assisted 3D printing technology provides a new solution for the efficient forming of tungsten carbide materials, maintaining product performance while reducing material waste.