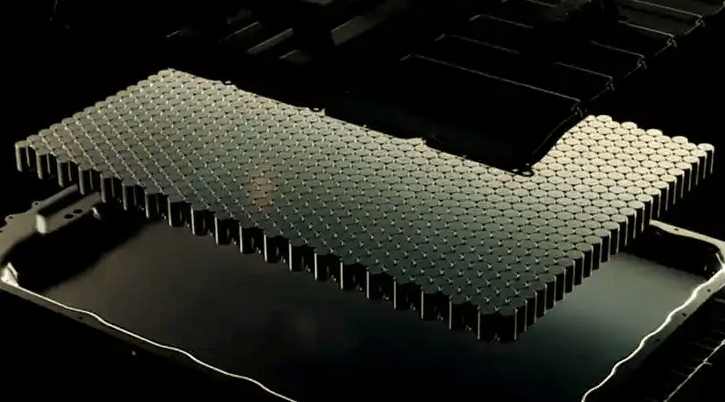

Wedoany.com Report on Feb 10th, The BMW Group, together with its partner Encory, recently established a new Battery Recycling Competence Center (CRCC) in Salching, dedicated to processing used batteries from electric vehicles and residual materials from battery manufacturing. This initiative aims to reduce reliance on primary mineral resources and lower the environmental impact of battery production through efficient resource recycling.

The battery recycling center employs innovative direct recycling technology, capable of extracting valuable raw materials such as lithium, cobalt, and nickel from electric vehicle batteries and directly reusing these materials in the production of new batteries. Compared to traditional recycling methods, this technology avoids energy-intensive chemical or thermal treatment steps, significantly reducing energy consumption and carbon emissions. At full capacity, the center is expected to produce several tons of high-quality battery materials annually, which will subsequently be transported to BMW's electric vehicle battery factory in Parsdorf, Germany, for the production of next-generation batteries.

The operation of the battery recycling center will be expanded in phases to ensure technological stability and efficiency. This collaboration not only enhances BMW's capabilities in sustainable supply chain management but also sets a benchmark for the circular economy across the entire electric vehicle industry. By optimizing battery recycling processes, companies can utilize resources more effectively, reduce waste, and drive the transition toward green energy.