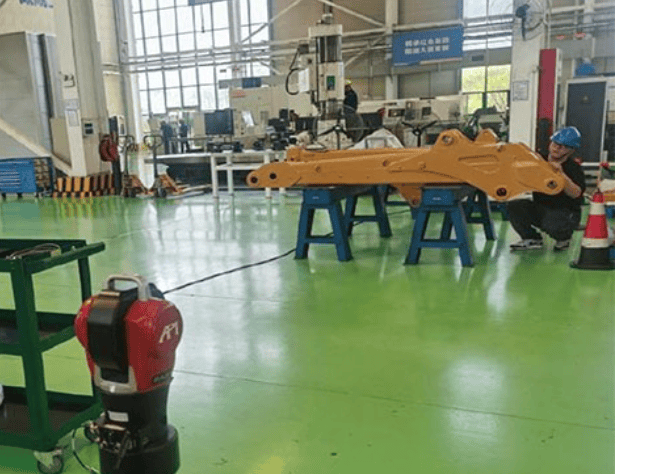

Wedoany.com Report on Feb 10th, In the high-end equipment manufacturing industry, the precision inspection of large boring and milling machining centers faces numerous challenges. A large manufacturing enterprise needed to inspect parts up to 5 meters long. Traditional coordinate measuring machine (CMM) methods struggled to meet the requirements for online dimensional control and the measurement of large-scale parameters such as coaxiality and parallelism. Furthermore, vibrations and temperature fluctuations in the workshop environment posed interference to high-precision measurements.

The company selected the API Radian Core laser tracker system as the solution. This system offers micron-level measurement accuracy and an 80-meter measurement radius, making it suitable for large machine tool inspection. High-precision spherically mounted retroreflectors (SMRs) are used for contact measurement. Combined with a portable control unit and measurement software, the system enables data acquisition and automatic report generation.

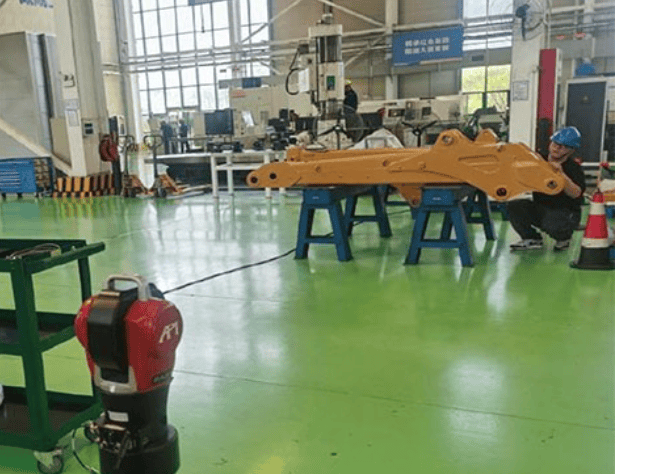

During on-site implementation, the laser tracker was positioned for clear line-of-sight based on the part size. Weighing less than 11 kilograms, it allowed for rapid deployment. By strategically selecting measurement stations and using a nest, data stitching was achieved. The software's temperature compensation system mitigated the effects of ambient temperature variations. Measurement software such as Polyworks can analyze parameters like hole diameters and coaxiality, and generate reports containing data tables and charts.

After introducing the API laser tracker, inspection efficiency improved significantly. The time required for part precision inspection was reduced from 1-2 days to half an hour, and machine downtime was minimized. Measurement accuracy reached the micron level, and the temperature compensation module ensured data reliability. Automatic reports can reflect part conditions and guide adjustments to machine tool parameters.

High-precision laser trackers are an effective tool for solving the challenges of inspecting large workpieces. They support rapid multi-dimensional measurement and data analysis, assisting machining enterprises in achieving digital quality management. In the future, the integration of laser trackers with machine tool systems is expected to drive real-time error compensation and intelligent development.