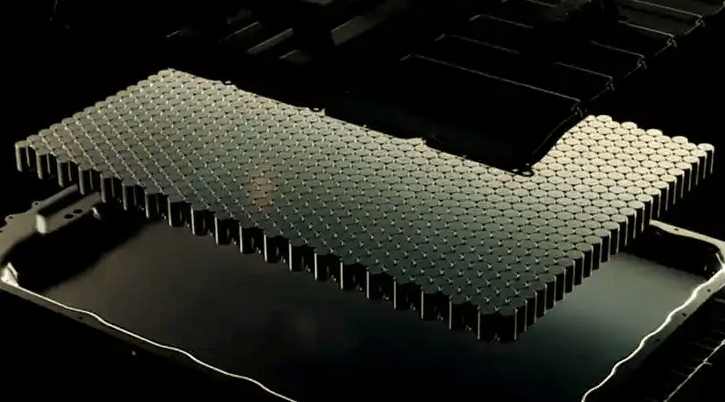

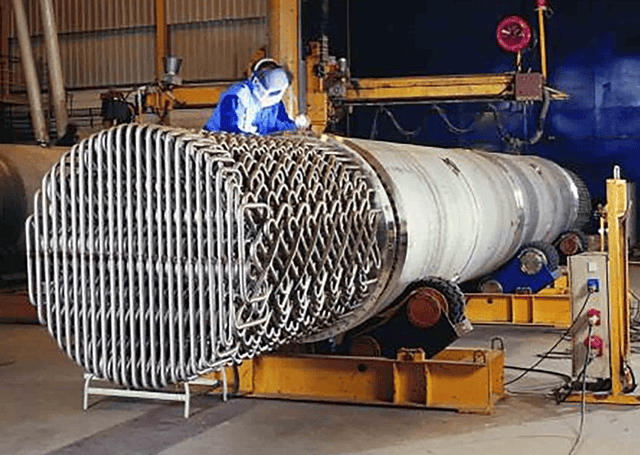

Wedoany.com Report on Feb 9th, As offshore wind projects advance into deeper waters and larger scales, the limitations of traditional welded steel joints in terms of manufacturing efficiency, fatigue performance, and inspection cycles are becoming increasingly apparent. Tree Composites proposes an innovative solution: replacing conventional welded nodes with non-welded, wrapped composite joints, aiming to enhance structural durability and adapt to existing offshore manufacturing processes.

In an interview, CEO Maxim Segeren stated, "We are addressing a major bottleneck in offshore construction: the fabrication of large welded joints for steel structures. The welding process is labor-intensive, time-consuming, and sensitive to fatigue-related failures. Our wrapped composite joints use a non-welded connection, enabling faster production, easier inspection, and significantly improved fatigue performance." These composite joints help reduce capital expenditure and carbon emissions while increasing production scalability, aligning with the demand for accelerated deployment of offshore wind in Europe's deep-water regions.

Since gaining recognition in the JEC Startup Booster in 2025, Tree Composites has progressed from laboratory validation to full-scale industrial demonstration. The company has refined the wrapping process for large-diameter joints, improved manufacturing consistency, and strengthened the correlation between numerical simulations and physical testing to demonstrate the predictability and repeatability of joint performance. Currently, the company has reached Technology Readiness Level 6 and is advancing towards Level 7, having produced and validated over 250 joints, including configurations for jacket foundations.

In 2025, as part of the WrapNode-II project, Tree Composites completed the first offshore jacket assembly incorporating composite joints at HSM Offshore, achieving full-scale industrial integration. The company has also expanded its industrial ecosystem, establishing new partnerships within the steel and glass fiber industries, and is working closely with developers and shipyards to prepare for offshore deployment and full production integration.

Despite the potential shown by composite joints in the offshore wind sector, their widespread adoption still faces obstacles. Maxim Segeren pointed out, "The key challenge lies in building confidence in the reliability and scalability of this new type of structural joint. Offshore developers, insurers, and EPC contractors need to be convinced of stable product performance, the ability for batch delivery, and integration into existing quality assurance systems." To this end, the company is advancing fatigue validation and methodology standardization through full-scale testing, rigorous material traceability, robust process control, and collaboration with institutions like Delft University of Technology.

This innovation opens new market opportunities for composite applications. A single offshore wind farm could involve the application of over 5,000 tons of composite joints. Tree Composites' technology not only introduces a new product but also enables composites to enter the market for large offshore structures. Since the JEC Booster recognition, the company has gained more supplier collaborations, increased investor confidence, and expanded its commercial network, further solidifying its role as an enabler in the offshore energy sector.