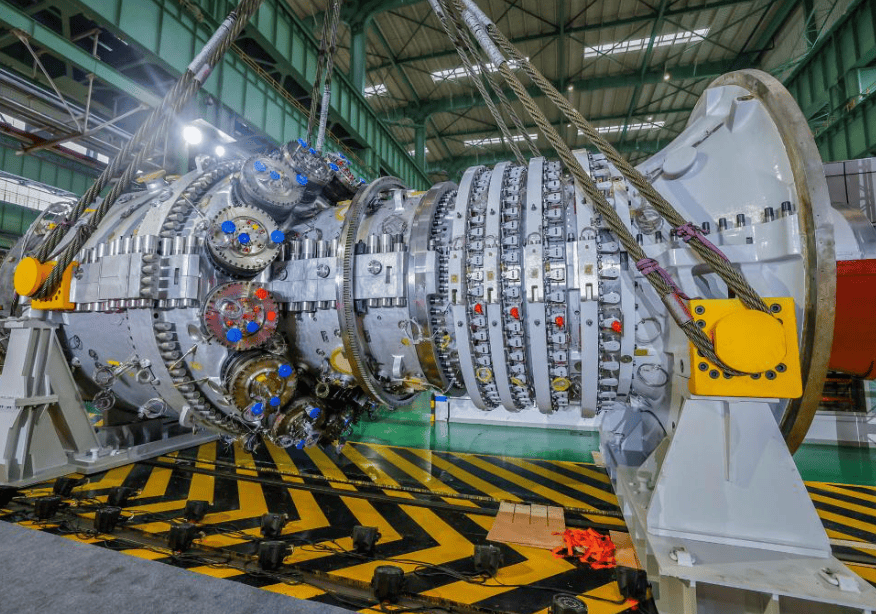

Wedoany.com Report on Feb 11th, the world's largest diameter shaft boring machine, "Qiming Hao," officially commenced operation. This equipment can perform vertical downward excavation, overcoming challenges related to efficiency and safety in traditional shaft construction. In the same year, China launched its first in-situ continuous large-diameter variable-diameter shield tunneling machine, "Bianjing Yihao," whose cutterhead excavation diameter can be continuously adjusted between 8.83 meters and 12.45 meters.

Lai Weilong, the technical lead for "Bianjing Yihao," stated: "This is thanks to the 'deformable skeleton' we installed for 'Bianjing Yihao,' which enables it to autonomously perform complex actions such as cutterhead expansion and skeleton reconstruction within the tunnel." This innovative technology enables continuous, uninterrupted construction between subway interval tunnels and platform-level tunnels.

In the field of hard rock tunneling, Zhang Guanghui, the technical lead for the "Jiaomei Hao" tunneling machine, explained: "The successful development of 'Jiaomei Hao' has explored a new path for rock tunnel excavation under complex geological conditions such as large cross-sections, steep inclines, and high stress." In its application at the Zhongmacun Mine of Henan Energy Jiaomei, this equipment achieved a single-month excavation record of 606 meters.

Currently, Chinese shield tunneling equipment has entered the global market. The super-large diameter shield tunneling machines "Patigarang" and "Barangaroo" exported to Australia have an excavation diameter of 15.7 meters. Chen Kunpeng, Chief Engineer of the International Business Division of China Railway Equipment, said: "Cutter replacement underwater is a widely recognized industry challenge. The cutter replacement robot not only reduces the operation time from 2 to 4 hours to 30 minutes but also fundamentally eliminates safety risks for personnel working in high-risk environments."

Shield tunneling products from Chinese enterprises now cover more than 30 countries and regions worldwide and have secured project orders in international markets such as Dubai and Austria. The localization rate of core components for shield tunneling machines has exceeded 90%, establishing export capabilities ranging from single equipment to complete solution packages.