In highly filled glass fiber reinforced polypropylene composites, flame retardant performance is primarily determined by additive dispersion rather than chemical composition. Favored in lightweight structural applications such as automotive and new energy vehicles for their high strength-to-weight ratio, dimensional stability, and cost advantages, these materials must meet stringent fire safety requirements.

Polypropylene is inherently difficult to flame retard, and its performance in fire tests like UL 94 is influenced by the combustion behavior of the formulation. Its high heat of combustion, approximately 46 MJ/kg, promotes rapid flame spread, while glass fibers exacerbate the fire via a wick effect, undermining the effectiveness of traditional flame retardant systems. Historically effective halogenated flame retardants have been phased out due to environmental and regulatory pressures in favor of halogen-free alternatives, such as polyphosphate-based systems. However, conventional ammonium polyphosphate formulations exhibit inconsistent performance in highly filled composites.

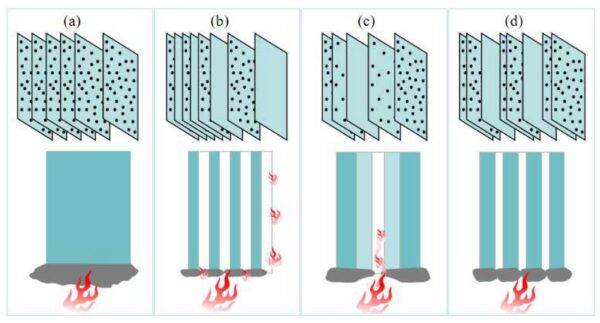

In formulations with high glass fiber content, additive dispersion becomes the dominant factor for flame retardancy. Poor dispersion not only reduces fire protection but also compromises mechanical properties. Ammonium polyphosphate-based systems are sensitive to processing temperatures, potentially leading to degradation and additive migration. Glass fibers amplify these weaknesses, and increasing flame retardant loading can worsen the problem.

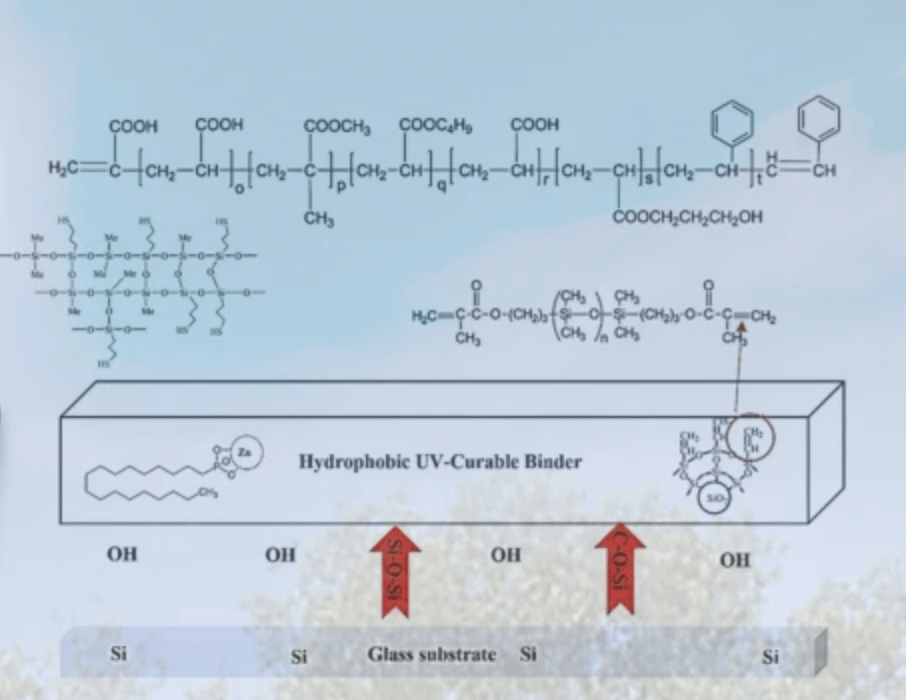

Non-ammonium polyphosphate flame retardants offer a new strategy by being supplied as highly active masterbatch concentrates, containing approximately 75% active material dispersed in a polypropylene carrier resin. This approach addresses dispersion issues before glass fiber addition, improving feeding accuracy, mixing uniformity, thermal stability, moisture sensitivity, and compatibility with the matrix.

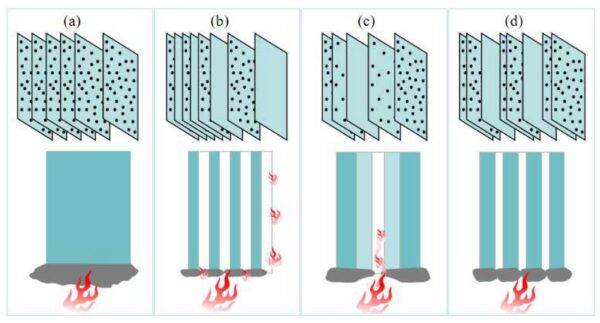

In formulations containing these masterbatches, flame retardant performance is enhanced through controlled distribution, forming a continuous, stable char layer that limits heat transfer and the supply of molten polymer, thereby weakening the wick effect. Fire tests demonstrate lower heat release rates and smoke density, with performance potentially matching that of PC/ABS systems.

The masterbatch system demonstrates excellent environmental tolerance, showing no surface blooming after heat and humidity exposure, stable mechanical properties after water immersion, and minimal performance loss during thermal cycling and UV aging tests. Formulations with higher thermal stability further expand the application scope, supporting long-term weathering requirements.

Non-ammonium polyphosphate masterbatch concentrates address fire protection, processing stability, and mechanical performance by controlling dispersion early on, enabling halogen-free flame retardancy while preserving material advantages. As the use of lightweight composite materials increases, flame retardant strategies are shifting focus towards dispersion control rather than merely adding chemical substances.