The U.S. Department of Energy's Oak Ridge National Laboratory (ORNL) has achieved a major breakthrough in electric vehicle (EV) batteries, bringing new hope for strengthening the competitiveness of the American transportation industry. Developing domestically produced EV batteries that enable rapid charging and long-range performance is key to boosting U.S. transportation competitiveness, but the energy density needed for extended range often comes at the expense of charging speed and battery life.

ORNL researchers have successfully manufactured a battery that combines outstanding energy density with enduring fast-charging capability by integrating a novel current collector. This battery can restore at least 80% of its charge in 10 minutes, while reducing metal usage—particularly high-demand copper—eases pressure on U.S. supply chains.

Lead researcher Georgios Polyzos stated that this technology significantly saves on near-critical materials, requiring much less copper and aluminum, while greatly enhancing the energy density achievable with a 10-minute charge.

The current collector, a key battery component, conducts current from the active material inside the battery to the external circuit, typically made of metal foil—one at each electrode end: copper for the anode and aluminum for the cathode. However, these metal foils add weight to the battery, increasing overall vehicle weight and energy required for propulsion.

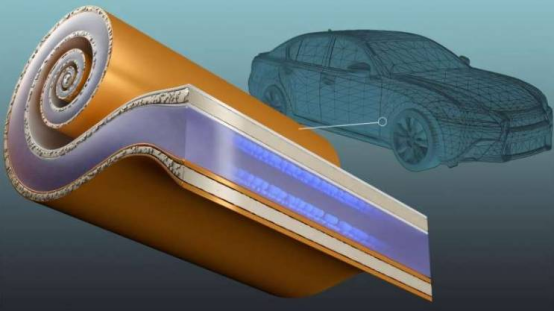

The new current collector, manufactured by industry partner Soteria Battery Innovation Group, is a polymer sandwiched between very thin layers of copper or aluminum. ORNL researchers found that this novel component reduces current collector costs by 85%, provides 27% additional energy for longer range, and maintains high energy density after 1,000 cycles. Even under extreme fast-charging conditions, its performance matches traditional collectors, but at about one-quarter the weight, enabling EVs to travel farther on the same charge.

To ensure scalability and commercialization, ORNL researchers manufactured coin cells and pouch cells using industry-standard processes at the Open Battery Manufacturing Facility. Polyzos noted that while thinner materials are more prone to wrinkling, the team identified precise parameters to integrate them into roll-to-roll production. Unlike other experimental collectors, this one is compatible with standard roll-to-roll methods, avoiding costly and complex manufacturing.