With support from the U.S. Department of Energy, Argonne National Laboratory is collaborating with industry to develop cost-effective nuclear fuel recycling technologies, unlocking the energy potential in nuclear waste and promoting sustainable nuclear power.

Nuclear reactors across the U.S. generate large amounts of spent fuel, over 95% of which retains valuable energy potential. Through advanced chemical processes and new technologies, scientists can recycle these materials to generate more electricity while significantly reducing long-term radioactive waste. Researchers are working to transform this potential into practical, scalable solutions.

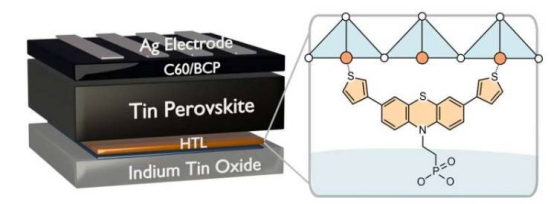

Argonne scientists are partnering with SHINE Technologies in Wisconsin to design a novel chemical process for separating valuable materials from spent fuel. The process uses innovative equipment like centrifugal contactors—devices that separate mixed liquids through rotation—to create a safer, more efficient, and industrially viable recycling method. The core goal is to develop a commercially adoptable, scalable recycling technology.

"Combining scientific research with industrial implementation is critical to solving complex challenges," said Candido Pereira, deputy director of Argonne's Chemical and Fuel Cycle Technologies (CFCT) division. "Our team leverages Argonne's expertise, facilities, and research capabilities to deliver world-class solutions to the private sector."

However, recycling spent nuclear fuel faces significant challenges: First, high radioactivity and heat generation require safe storage and cooling before processing. Facilities need robust systems to protect workers from radiation and manage residual radioactive materials. Second, nuclear material security is paramount. Fresh, stored, or recycled fuel must be strictly safeguarded against unauthorized access or misuse. Scientists follow "safeguards-by-design" principles to minimize risks of diversion for non-peaceful purposes, with strong security and monitoring systems essential for national security and international compliance.

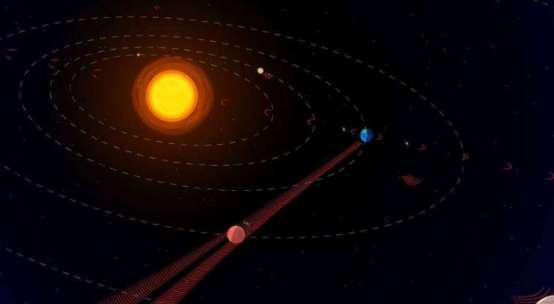

Beyond technical and safety considerations, economic viability is key. Recycled materials need buyers and practical applications. Some utilities may be interested in using recycled fuel in advanced reactors, while valuable byproducts like radioisotopes can power deep-space missions or enable life-saving medical diagnostics. Commercial demand for these materials would make recycling facilities more economically attractive.

A successful recycling process must also be forward-looking. Scientists must account for how different reactor designs use fuel and what materials future reactors will require. Experts at national labs like Argonne, with unique capabilities, can accurately forecast and adapt recycling methods accordingly.

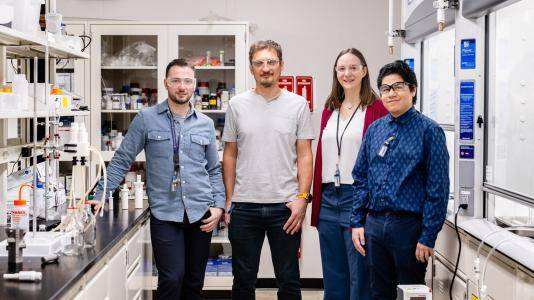

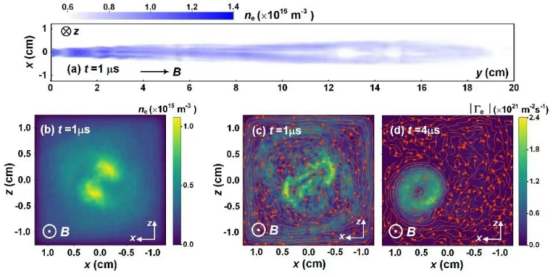

Peter Tkac, manager of the Radiochemistry Group in Argonne's CFCT division, leads the team tackling this challenge. Tkac noted that handling pure plutonium poses risks and burdens, so "optimizing separation steps and developing a process that avoids producing a pure plutonium stream is critical." In a lab-scale environment, Tkac's team simulates high-radiation conditions of recycling facilities to test separation processes. They use Argonne's Van de Graaff electron accelerator—a particle accelerator that generates high voltage via static electricity—to mimic spent fuel behavior during processing. Particles striking targets produce minimal radioactivity, allowing controlled study of chemical degradation over time without heavy shielding.

These lab-scale tests provide critical data for SHINE and partners to scale up technologies. Ross Radel, SHINE's Chief Technology Officer, said: "SHINE has previously collaborated with Argonne to improve medical isotope production, saving countless lives domestically and globally. We believe this partnership to reduce waste through spent fuel recycling will remove a major barrier to nuclear power expansion, ensuring abundant future energy."

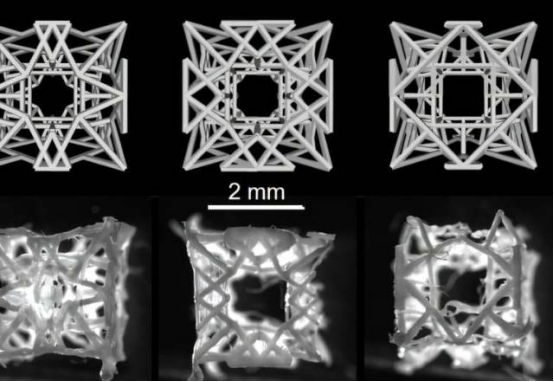

Currently, Tkac's team is working with SHINE to test equipment for large-scale facilities, with centrifugal contactors as a key technology. These devices efficiently separate complex mixtures with high throughput and small footprint. Researchers use 3D printing to build custom components, enabling rapid, low-cost design testing. Prototypes are tested under real chemical conditions with minimal radioactive waste, ideal for early development before industrial scaling. Tkac explained: "Argonne's centrifugal contactor technology separates highly complex mixtures efficiently, effectively, and compactly. We have a strong nuclear fuel recycling strategy—the specific method will depend on the reactor technology chosen for energy production."

As demand for clean, reliable electricity grows, nuclear power is regaining momentum. While it's too early to predict which reactor design will dominate, nuclear energy is reemerging as a reliable solution to 21st-century energy challenges. Tkac said: "Recycling spent nuclear fuel is an extremely complex process, heavily dependent on which technology prevails and electricity demand. We need a solid strategy."

This work is supported by the DOE Office of Technology Commercialization through the Technology Commercialization Fund. The Argonne-SHINE collaboration operates under a Cooperative Research and Development Agreement, leveraging Argonne's scientific expertise and SHINE's commercial experience to advance nuclear fuel recycling.

京公网安备 11010802043282号

京公网安备 11010802043282号