In nature, bees, ants, and termites build magnificent nests through collective action, relying solely on worker ants or drones responding to signals like temperature and building materials—without blueprints or central planning. Inspired by this, researchers at the University of Pennsylvania's School of Engineering have developed mathematical rules enabling virtual micro-robot swarms to construct honeycomb-like structures in computer simulations without following any plan or even understanding it, opening new possibilities for manufacturing.

Jordan Raney, associate professor of mechanical engineering and applied mechanics and co-senior author of the new paper in Science Advances, stated that while this research is just the first step, the new strategy could lead to a new paradigm in manufacturing. Traditional manufacturing, such as 3D printing, operates step-by-step according to precise instructions, making the process fragile—a single error can ruin the entire operation. In contrast, the new strategy is more robust, as construction is not interrupted by a single robot's mistake, and it is more adaptable, capable of building complex structures on-site.

Human engineering, from stone tools to space stations, has always relied on planning—envisioning the final result and designing the construction step-by-step, with 3D printing being no exception. However, the Penn team's approach is distinct, bypassing this traditional paradigm. Ruzena Bajcsy, director of the General Robotics, Automation, Sensing and Perception (GRASP) Lab, and Mark Yim, another co-senior author, explained that the method involves no pre-written scripts or centralized planning; each robot simply reacts to its surroundings. Individual robots do not need to understand the big picture, and even if some malfunction or deviate from their path, construction continues. Moreover, all robots operate simultaneously, potentially making the entire process faster in the future and more resilient to individual robot failures.

Although inspired by nature, the researchers did not precisely mimic the behaviors of natural builders like bees and ants, nor did they seek design clues from learning algorithms in brains, as some AI researchers do. Instead, they focused on deeper principles in nature: simple behaviors repeated many times can create complex and useful things. Raney said they wanted a system where the structure emerges from behavior, with robots following the right local rules rather than knowing what they are building. The challenge lies in determining these rules—there are numerous ways to program robots to react to their environment, and the range needed to be narrowed to simple yet useful rules.

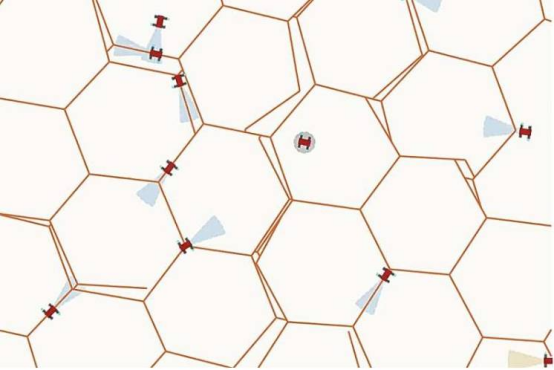

The team focused on solving several basic issues, such as how robots react when colliding with objects built by others, turning angles, walking distances, and more, generating about a dozen variables. The researchers studied these variables through multiple simulations, fine-tuning key rules by simulating robot activities. They ultimately found that the degree of disorder in the system is crucial to the final structure—the more parameters changed, the greater the variation in the final structure. Adding an appropriate amount of disorder to honeycomb-like structures can enhance their toughness, and the team identified "levers" that alter the geometry of the final product, thereby affecting its crack resistance.

Although the team has created prototypes, they are still far from building real robot swarms. They plan to first update the simulation system to better reflect how micro-robots operate in the real world. Early models assumed robots lay down material in straight lines like mini 3D printers, but electrochemical methods that allow robots to grow metal structures around themselves may be more practical. Achieving this requires advances in manufacturing micro-robots capable of moving, sensing, and interacting with materials. However, the team believes the concept itself represents a significant advancement, hoping it will encourage people to think in new ways about how things are built, learning from nature's method of aggregating countless tiny actions into grand spectacles.

Other co-authors include co-first authors Jiakun Lu and Xiaoheng Zhu, as well as Walker Gosrich, all from the University of Pennsylvania's School of Engineering.