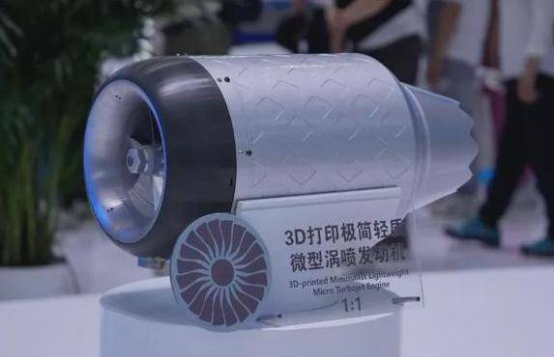

According to China Aero Engine Corporation (AECC), on July 1, a 3D-printed ultra-simplified lightweight miniature turbojet engine, independently developed by AECC Hunan Aero Engine Research Institute, successfully completed its first flight verification on a test platform in Inner Mongolia. The engine employs multidisciplinary topology optimization and additive manufacturing technology, achieving a revolutionary fusion of innovative aero-engine design concepts and manufacturing processes, and filling a domestic gap in the engineering application of complete engines in this technical field.

This engine is China's first 160kgf thrust-class multidisciplinary topology-optimized additively manufactured turbojet to successfully complete flight verification. The R&D team overcame the limitations of traditional design and manufacturing methods, successively conquering key technologies such as multidisciplinary topology optimization design tailored for additive manufacturing and integrated component design. This dramatically reduced the engine's structural weight and significantly improved critical performance indicators. Prior to the flight, the engine had already passed key ground tests, including full-engine performance validation and full-engine life testing, ensuring the success of the flight verification on the first attempt.

The flight verification was carried out strictly according to the planned program, reaching a maximum altitude of 4,000m above sea level, fully validating the engine's reliability and stability under real flight conditions. The successful maiden flight lays a more solid technical foundation for the subsequent development of advanced aero-engines.