In the quest for higher-efficiency solar cells and other electronic devices, scientists never cease exploring novel semiconductor materials. Yet the slow pace of manually measuring key material properties has long been a major bottleneck to innovation. Now, MIT researchers have developed a breakthrough fully autonomous robotic system that solves this challenge.

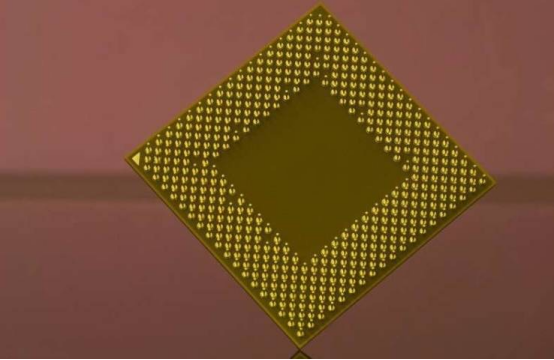

The system uses a robotic probe to focus on measuring photoconductivity — the critical electrical response of a material to light. The team embedded deep human expertise in materials science into a machine-learning model that guides the robot's decisions, enabling it to precisely identify the best locations for probe contact and gather rich photoconductivity data. A dedicated path-planning program then determines the fastest route for the probe between contact points.

In a rigorous 24-hour test, the fully autonomous robotic detector demonstrated remarkable efficiency, completing more than 125 unique measurements per hour — with results that were more accurate and reliable than other AI-based approaches.

Tonio Buonassisi, Professor of Mechanical Engineering and senior author of the autonomous systems paper, praised the achievement: "This paper is groundbreaking — it opens the door to autonomous, contact-based characterization methods. Not all critical material properties can be measured contactlessly. When contact with the sample is required, speed and maximal information extraction become essential." The findings will be published in Science Advances. Co-authors include graduate student Alexander (Aleks) Siemenn (first author), postdoctoral researchers Basita Das and Kangyu Ji, and graduate student Fang Sheng.

Researchers at the Buonassisi Sustainable Accelerated Materials Lab are working toward a fully autonomous materials discovery laboratory, with recent focus on discovering new perovskites — semiconductor materials used in solar panels and other photovoltaic technologies. Previously, they developed techniques for rapidly synthesizing and printing unique perovskite compositions and designed imaging-based methods to determine some key material properties. However, photoconductivity characterization requires placing probes on the material, shining light, and measuring the electrical response.

To make the lab highly efficient, the team integrated machine learning, robotics, and materials science into a single autonomous system. The system first captures images of perovskite-printed glass slides using an onboard camera, then uses computer vision to segment the image into regions. These regions are fed into a neural network model infused with expert knowledge from chemists and materials scientists. The model determines the optimal probe contact points based on sample shape and composition, while a path planner identifies the most efficient route to visit all points.

This machine-learning approach is highly adaptable because printed samples vary widely in shape — from circular droplets to gummy-bear-like structures. Speed is achieved through the model's self-supervised nature: it directly identifies optimal contact points on sample images without needing labeled training data. Additionally, by introducing a small amount of noise or randomness into the path-planning algorithm, the researchers successfully found the shortest paths.

After system assembly, component tests showed that the neural network model found more accurate contact points in less computation time than seven other AI-based methods, while the path-planning algorithm consistently produced shorter routes. In a 24-hour fully autonomous experiment, the robotic system performed more than 3,000 unique photoconductivity measurements at a rate exceeding 125 per hour.

This precise measurement approach not only provides rich detail — helping researchers identify high-photoconductivity hotspots and material degradation zones — but also opens the door to discovering and developing new high-performance semiconductors, with major implications for sustainable applications like solar panels. As Siemens noted, "Being able to collect such rich data so quickly without human guidance opens entirely new possibilities for semiconductor materials research."

The team now aims to continue refining the robotic system, advancing toward the goal of a fully autonomous materials discovery laboratory and injecting powerful momentum into materials innovation for high-end device manufacturing.