Intermediate-temperature reversible protonic ceramic electrochemical cells (PCECs) combine electrolysis (EC) for hydrogen production and fuel-cell (FC) power generation, making them a promising new energy storage solution for grids handling intermittent renewables and dynamic peaking. However, current PCECs suffer from limited performance: at low steam partial pressure (3–12% pH₂O) they operate only hundreds of hours with high degradation (>10µV/h), while under industrially relevant high steam pressure (≥40%) degradation surges dramatically (280–787µV/h). Even the best button-cell record (1,833h, 12% pH₂O, 40µV/h) falls far short of requirements for large-scale deployment.

The core conflict driving PCEC degradation is the inherent chemical instability of conventional barium cerate electrolytes (e.g., BZCYYb) and TCO oxygen electrodes under high steam pressure (≥40%), compounded by "planar contact" defects from screen-printing processes. This creates a triple dilemma at the porous electrode / dense electrolyte interface: electrode porosity continuously exposes the electrolyte to steam, triggering phase decomposition; low-temperature sintering results in weak interfacial bonding; and TCO materials struggle to simultaneously achieve high proton conductivity, stability, and electrocatalytic activity — ultimately causing sharp rises in interfacial resistance, blocked proton transport, and cyclic degradation.

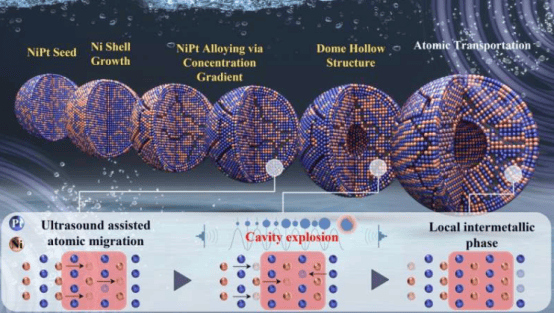

A research team led by Prof. Xingbo Liu (West Virginia University), Wei Li, and Prof. Kai He (University of California) constructed a porous proton-conducting scaffold conformally coated with Pr₁.₈Ba₀.₂NiO₄.₁ electrocatalyst. The scaffold exhibits high chemical stability to water, triple conductivity, and hydration capability, protecting the fragile electrolyte from water attack. The Conformal-Coated Scaffold (CCS) architecture strengthens electrode–electrolyte interfacial bonding and enables rapid proton transport through a percolating network.

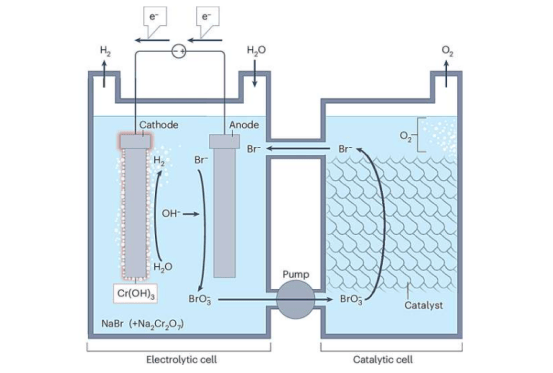

With this design, PCECs achieved 5,000 hours of electrolysis stability at -1.5A cm⁻² and 600°C under 40% H₂O, and 1,018 hours of FC stability with zero degradation. The team also demonstrated a unitized regenerative PCEC (UR-PCEC) prototype integrating the CCS cell with hydrogen cycling and storage modules, enabling frequent EC/FC switching and long-duration deep cycling without external H₂ supply.

The Conformal-Coated Scaffold (CCS) design proposed in the study addresses the chemical instability of electrolytes and oxygen electrodes under high steam concentration and poor electrode–electrolyte contact in conventional PCECs by building a porous proton-conductive scaffold uniformly coated with steam-resistant, highly active Pr₁.₈Ba₀.₂NiO₄.₁ (PBNO) oxygen electrocatalyst. In the CCS structure, PBNO serves as a continuous defect-free protective film tightly wrapping the porous electrolyte scaffold and dense electrolyte, isolating water vapor attack while expanding the proton-conducting network.

CCS-based PCECs exhibit outstanding long-term stability under high-steam conditions: 5,000h electrolysis stability with degradation rate of only 1µV h⁻¹, and 1,018h degradation-free operation in fuel-cell mode. The team also successfully developed an integrated regenerative PCEC (UR-PCEC) prototype that achieves frequent EC/FC mode switching and extended stable operation without external hydrogen supply.

This holistic mitigation strategy comprehensively resolves the limited operational stability, poor electrode–electrolyte contact, and proton transport issues of traditional PCECs under high steam concentration. The porous electrolyte scaffold uniformly coated with steam-resistant, highly active PBNO oxygen electrocatalyst stabilizes various barium-cerate-based proton-conducting electrolytes and demonstrates potential for large-scale CCS cell manufacturing. PCECs show high chemical stability to water, strong PBNO–electrolyte interfacial bonding, percolating proton conduction network, and thermo-mechanical stability against temperature fluctuations, delivering -1.3A cm⁻² electrolysis current density at 1.28V and 600°C under 40% H₂O with Faraday efficiency of 77.6%. The CCS architecture also holds significant implications for solid-state batteries, heterogeneous catalysis, and other ceramic-based energy devices.