Complex tubing is a critical component in aero-engines, rockets, and other equipment, incorporating diverse elements such as flanges and joints, resulting in highly intricate structures. Ensuring dimensional accuracy of these tubes is essential for stable operation of the associated equipment.

Recently, a research team from the Shenyang Institute of Automation (SIAC), Chinese Academy of Sciences, achieved significant progress by developing an online measurement method based on multi-camera vision and region pre-segmentation, enabling real-time, high-precision detection of spatial dimensions for flanges and jointed tubes. The related research has been published in the Journal of Manufacturing Processes.

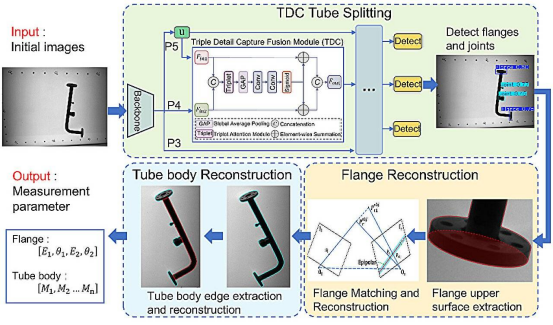

The team introduced a Triple Detail Capture (TDC) fusion-based segmentation model that effectively integrates multi-scale visual features, allowing the system to accurately identify key structural regions such as flanges and joints for precise segmentation.

For quantifying flange geometry, the researchers proposed an edge-based measurement algorithm focused on the flange upper surface. By analyzing curvature variations and applying 3D reconstruction, precise parameter extraction is achieved. For tube body regions that are typically linear but fragmented, the team reconstructed the central axis to determine key spatial measurements.

Experimental results show that the system completes full-tube measurement in just 7s, achieving flange parameter accuracy of 0.17mm and tube body parameter accuracy of 0.16mm, fully meeting the stringent aerospace manufacturing requirements.