Every year, 10% to 20% of technical failures in power system enterprises are related to human error. Traditional professional training costs up to 100,000 rubles per person and mainly teaches general knowledge, without allowing trainees to practice on specific facilities. Recently, scientists at Perm Polytechnic University demonstrated a unique 3D simulator, with related results published in the journal Vestnik PNIPU. Electrical Engineering, Information Technologies, Control Systems.

Electricity is the foundation of modern society, and its distribution involves multiple complex stages: generation, transformation, high-voltage transmission, and final delivery to consumers. Although the power generation industry has achieved automation and digitalization, human errors still occur during power plant maintenance, potentially leading to local power outages, power plant failures, or even emergencies such as fires or explosions. Such accidents are mainly caused by workers' lack of practical training, violation of regulations and safety precautions, and young professionals often lacking skills in operating actual equipment.

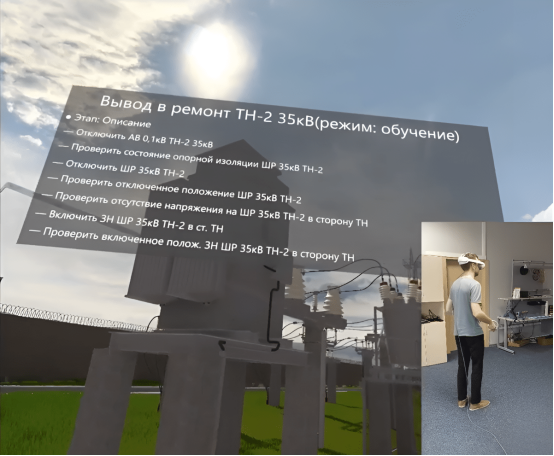

Virtual reality technology is an effective means to improve the capabilities of existing personnel and teach students practical knowledge. The 3D simulator developed by scientists at Perm Polytechnic University is based on the Unity platform. During development, the substation area terrain was first fully scanned, followed by the creation of 3D models of each project element, including the external environment of facilities and electrical equipment, constructing a controllable and movable virtual space to achieve maximum immersion.

When creating the simulator, each scenario in the program was written separately, prioritizing operations most commonly encountered in personnel activities, operations that identify gaps in safety precaution knowledge, and operations that may lead to dangerous emergencies and significant economic losses. In VR, users can select tools and protective measures to perform tasks, such as disassembling a voltage transformer for maintenance. The program suggests the correct operation sequence and checks the content; errors are pointed out with specific reasons. Other scenarios, such as quick switching of electrical equipment, connecting new objects, or simulating potential hazardous situations (short circuits, fires), are implemented in a similar manner.

The developers have tested the 3D simulator in the production process. Preliminary results show that emergencies involving human factors have decreased by 3%, making it an effective tool for reducing systemic risks in the long term. However, the scientists note that for the correct development and implementation of such simulators in enterprises, it is necessary to analyze emergencies caused by human factors and identify situations that can be effectively eliminated through human factors, as some accidents may be caused by fatigue, stress, or organizational factors.

Currently, the 3D simulator can be used for teaching in enterprises and higher and secondary vocational education institutions. It is planned to be applied in the training of students majoring in “Power Supply” at Perm National Research Polytechnic University (PNRPU), and it can also be used for electrical safety certification and recertification of enterprise personnel. This 3D simulator from Perm Polytechnic University opens a new pathway for training power professionals and helps reduce accidents caused by human factors.