In the large-scale adoption of electric vehicles (EVs), battery performance and lifespan are key limiting factors. However, EU researchers are working on an innovative technology that could enable batteries to quickly detect damage and self-heal, bringing new hope to EV development.

Current EV sales in Europe are growing rapidly, with February sales up 20% compared to the same period in 2024. EVs are vital for electrifying transportation and reducing carbon emissions, but face many challenges. Most EVs rely on lithium-ion batteries, which are large, structurally complex, contain tens of kilograms of valuable metals like lithium, nickel, and copper, and need to last more than ten years to match vehicle life expectancy.

To address this, the EU-funded “PHOENIX” research team was formed. The team aims to develop self-healing batteries to extend battery life, improve safety, and reduce demand for new battery metals. Material scientist Ziegler from the Fraunhofer Institute for Silicate Research (ISC) in Germany stated that this can both prolong battery life and reduce carbon footprint and resource needs. In 2023, the EU identified 34 critical materials, including battery metals such as lithium, nickel, copper, and cobalt.

The “PHOENIX” project is named after the mythical bird that regenerates, symbolizing the researchers’ hope for battery technology rebirth and revival. With EU legislation requiring all new passenger cars and vans sold from 2035 to be zero-emission to drastically reduce greenhouse gas emissions in transportation, better batteries are urgently needed for EVs.

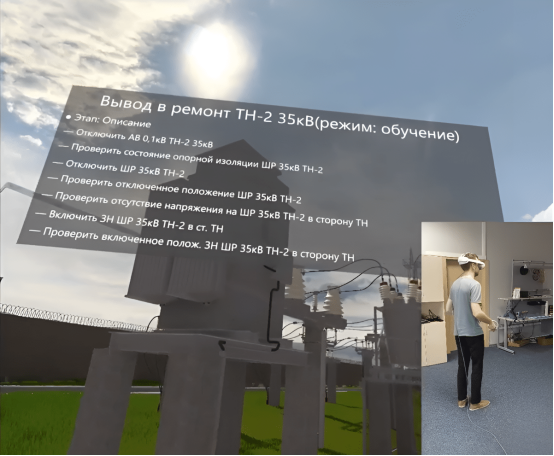

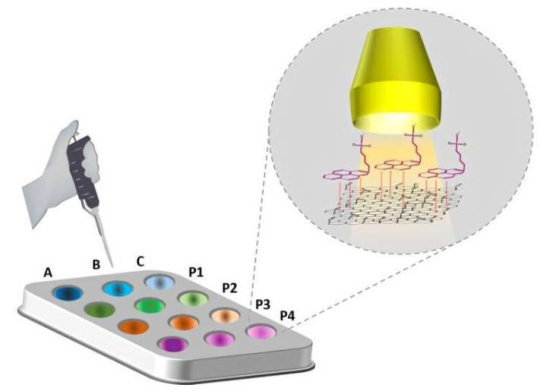

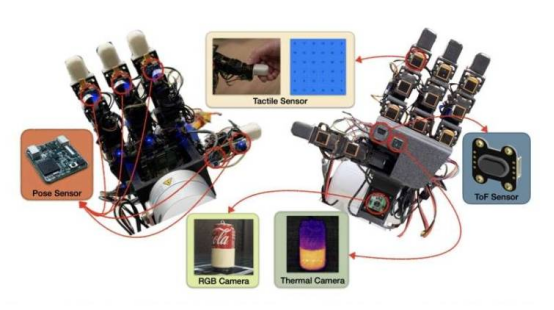

Scientists from Belgium, Germany, Italy, Spain, and Switzerland are collaborating to design sensors that detect aging changes in lithium-ion batteries and trigger self-healing, aiming to double battery lifespan and thus extend EV life. While current battery management systems (BMS) monitor voltage and temperature for safety, sensor measurement range is limited. The PHOENIX team plans to introduce advanced sensors and triggers—some detect battery swelling, some generate thermal maps, and some monitor hazardous gases—providing an early warning system for battery health. When the battery’s “brain” decides repair is needed, mechanisms such as squeezing the battery, applying heat, or using magnetic fields to break down dendrites are activated to prevent short circuits and failures.

In addition, PHOENIX researchers are working to increase EV driving range and reduce battery size. They are developing next-generation batteries with higher energy density, planning to replace graphite with silicon. However, silicon has poor stability and expands significantly during charge/discharge, so batteries need to withstand this or enable self-healing.

In March 2025, a new batch of sensor prototypes and triggers was developed and sent to partners for testing in pouch cells. However, installing sensors on batteries increases costs, so the team is focused on identifying technologies that deliver sufficient benefits to justify the cost.

Whichever approach ultimately succeeds, future EVs will have longer service life and greater range, equipped with safer, more compact batteries with lower resource intensity. Extending battery life also reduces the carbon footprint of EVs, creating a win-win for consumers and the environment. Ziegler remarked: “Extending battery life and developing EVs is exciting—the key is assembling all the components together.”