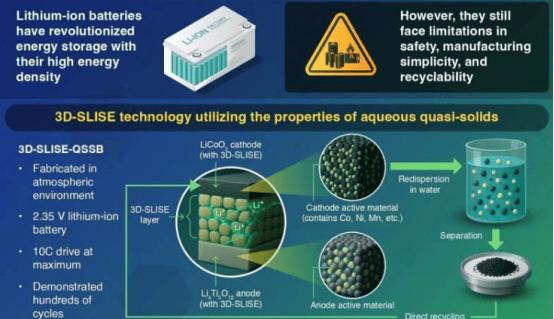

A research team from the Tokyo Institute of Science in Japan has developed a new type of quasi-solid electrolyte called 3D-SLISE, bringing breakthroughs in the safety and sustainability of lithium-ion batteries. The research results, published in Advanced Materials, demonstrate the potential of this technology to manufacture 2.35V batteries under normal temperature and pressure conditions.

The research team, led by Professor Yosuke Shiratori and Associate Professor Shintaro Yasui, developed this electrolyte material using a water-based borate matrix, avoiding the use of organic solvents in traditional battery production. Professor Shiratori stated: "Our goal is not only to improve performance but also to ensure safe and simple production."

Experimental data show that lithium-ion batteries using 3D-SLISE can achieve rapid charge-discharge in 20 minutes at room temperature and maintain stability over 400 cycles. The material has an ionic conductivity of 2.5mS/cm and an activation energy of only 0.25eV. Associate Professor Yasui noted: "This technology can also directly recover valuable materials such as cobalt, improving resource utilization."

The researchers indicated that the production of this electrolyte material does not require a dry room or high-temperature processing, and the electrode materials can be recovered through simple water washing, significantly reducing production costs and environmental risks. This technology holds promise for applications in consumer electronics and energy storage systems.