For consumers concerned about the usage risks of lithium-ion batteries (used in cell phones, laptops, electric vehicles, etc.), Michigan State University has a new finding: a natural material from wood can improve battery safety while extending its lifespan.

Assistant Professor Chengcheng Fang from the College of Engineering and Associate Professor Mojgan Nejad from the College of Agriculture and Natural Resources collaborated to design a thin-film separator using lignin (a natural component that provides support and rigidity to wood) for use inside lithium-ion batteries, preventing short circuits that could cause fires. Professor Fang said: “We want to make better batteries, and we also want them to be safe, efficient, and sustainable.”

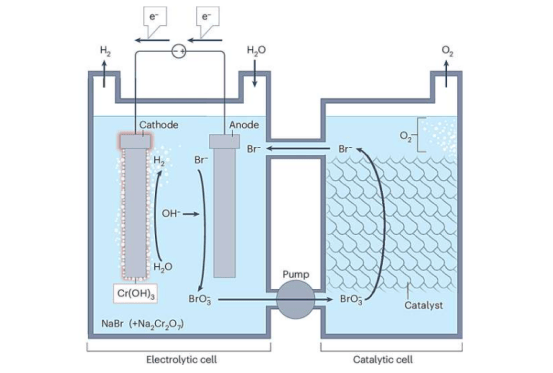

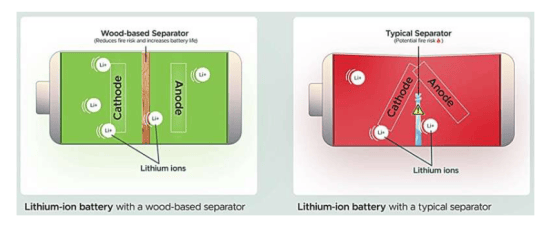

Inside the battery, the positively charged cathode and negatively charged anode help current flow. Commercial separators are typically made of polyethylene and polypropylene plastic, which shrink at temperatures close to 100°C. Without separator protection, the cathode and anode may come into contact, leading to unexpected short circuits that can cause fires or explosions. In contrast, the newly developed lignin-based separator remains stable at temperatures up to 300°C and does not shrink in size.

Professor Fang and the team tested different thicknesses of lignin and found that a 25-micron film (thinner than a quarter of a human hair) best maintains internal battery stability and prevents connection between the anode and cathode.

Using lignin thin films inside batteries also has additional benefits: improved internal stability increases cycle life (the number of times the battery can be charged and used). Professor Fang said: “We were surprised to find that the lignin film also increased the battery cycle life by 60%.”

The third advantage of this study is environmental friendliness. The team was able to use a low-cost dry processing method to manufacture lignin separators, enabling mass production of lignin films on demand while avoiding the use of harmful solvents commonly used in traditional separator manufacturing, reducing environmental harm. The researchers were able to manufacture films using lignin and other materials with 100% raw material conversion, producing no waste or pollution. Professor Fang said: “Lignin, especially lignosulfonate, is naturally abundant and can play a role in batteries without further processing. This study demonstrates a new design pathway to improve battery material safety and manufacturability.”

The research was published in Advanced Materials, and the related technology is currently being patented through Michigan State University’s Innovation Center.