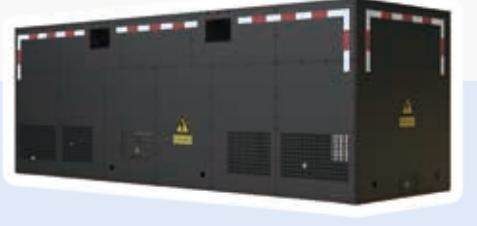

Ultra-Long Endurance · Specialized for Mining Heavy-Duty Applications

Core Highlights

- Powerful Performance: 800 kWh-class ultra-large capacity, meeting the long-duration, high-intensity operational demands of mining trucks.

- Top-Tier Battery Cells: Utilizes high-quality CATL (Contemporary Amperex Technology Co. Limited) battery cells, offering safety, reliability, and long cycle life.

- Robust and Reliable: Reinforced structural design, specifically built for harsh mining conditions, with excellent durability.

- Intelligent Thermal Management: Efficient thermal management system ensures stable battery operation under extreme temperatures (-35℃ to +60℃).

- Convenient Battery Swap: Standardized interface and structural design support rapid battery swapping, maximizing operational uptime.